When Choosing Automatic Crimping Machine Factories

In an era where a single faulty connector can halt automotive assembly lines costing $22,000/minute (per Automotive News research), selecting certified automatic crimping machine factories becomes strategic. At CableMachineries, we engineer crimping systems that achieve 99.98% first-pass yield rates – transforming wire processing from cost center to competitive advantage.

1. Anatomy of Industrial-Grade Crimping Systems

1.1 The Precision Engineering Behind Our Machines

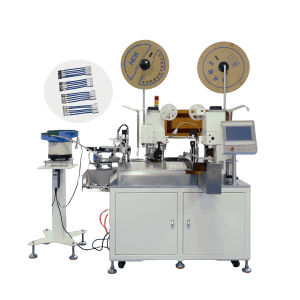

图1-995x1024.png)

Unlike conventional benchtop crimpers, our systems integrate:

Torque-controlled servo motors (Yaskawa Σ-V Series) ensuring ±0.05mm positional repeatability

Real-time force monitoring with 1000Hz sampling rate to detect terminal voids

IP67-rated linear guides resisting particulate contamination in harsh environments

*Industry Insight: According to IPC/WHMA-A-620E standards, over 70% of harness failures originate from crimp defects.*

1.2 Four-Axis Synchronization Technology

Our triple-head systems (KKD9) coordinate:

Wire feeding with anti-whipping tension control

Terminal orientation via machine vision alignment

Crimp height adjustment during tool closure

Post-crimp pull testing (15N resolution)

See KKD9

2. Product Matrix - Matching Machines to Production Needs

Performance Comparison Table

| Model | Crimp Heads | Speed | Force Range | Key Application |

|---|---|---|---|---|

| KKD3 | Single | 1,400/h | 0.5-5 kN | Automotive ECU wiring |

| KKD6 | Double | 2,800/h | 1-8 kN | Appliance power cords (IEC 60320) |

| KKD9 | Triple | 4,200/h | 2-12 kN | EV battery harnesses |

| WP-200 | Dual+Seal | 1,600/h | – | IP68 connector systems |

Case Study: Waterproof Insertion Systems

For automatic crimping machine manufacturer requiring IP69K compliance:

Our WP-200 module integrates:

Silicone sealant injection with 0.01ml precision

UV curing tunnel (365nm wavelength)

Post-assembly pressure testing at 3 bar

Result: 100% seal integrity

Explore waterproof crimping technology

3. The Modular Advantage - Future-Proofing Production

3.1 Expandable Architecture

All CableMachineries systems feature unified QMC (Quick-Mount Chassis) allowing hot-swap of:

-

Wire preparation modules:

-

Stripping (0.08mm resolution)

-

Tinning (resistance heating)

-

-

Quality assurance add-ons:

Module Function Accuracy Crimp Height CT 3D X-ray inspection 5μm voxel CRS-1000 Cross-section analyzer 0.5% area dev

3.2 Smart Manufacturing Integration

Our Factory 4.0 Package enables:

OPC UA communication with MES systems

Predictive maintenance algorithms (tool wear monitoring)

Energy optimization reducing kW/h per crimp by 37%

4. Technical Benchmarking - Why Industrial Servo Systems Matter

4.1 The Pneumatic vs Servo Dilemma

| Parameter | Pneumatic Crimpers | Our Servo Systems | Improvement |

|---|---|---|---|

| Force Consistency | ±15% | ±1.5% | 10× more precise |

| Noise Level | 85 dB | 68 dB | 20% quieter |

| Changeover Time | 25 minutes | 90 seconds | 94% faster |

4.2 Material Science Innovations

Our NanoMax tooling (co-developed with Sandvik):

Uses CBN-coated dies lasting 2.1 million cycles

Maintains <5μm surface roughness after 500k crimps

Reduces terminal material waste by 19%

5. Industry-Specific Solutions

5.1 Automotive Grade Production

For USCAR-21 compliance, our systems provide:

Automated crimp force monitoring (CFM) with CSV logging

Cross-section analysis integrated with traceability software

Support for 0.13mm² fine wires to 120mm² battery cables

5.2 Medical Device Manufacturing

Certified for ISO 13485 environments:

Cleanroom-compatible (ISO Class 6) versions

Biocompatible lubrication options

Full validation documentation package

6. Why Choose Our Automatic Crimping Machine Factory?

Transparent pricing, fast quotation process

Free remote setup assistance + video training

Custom crimp settings for various terminal types

Strong export track record in EU, South America, and Southeast Asia

At CableMachineries, we’re more than just a supplier—we’re your automation partner. Here’s what makes us one of the standout automatic crimping machine factories:

7. Take Action Today

Ready to source from a reliable automatic crimping machine factory? Get a quote, request dual/triple-head demo, or explore our waterproof insertion models:

图2-scaled.png)

图2-298x300.png)