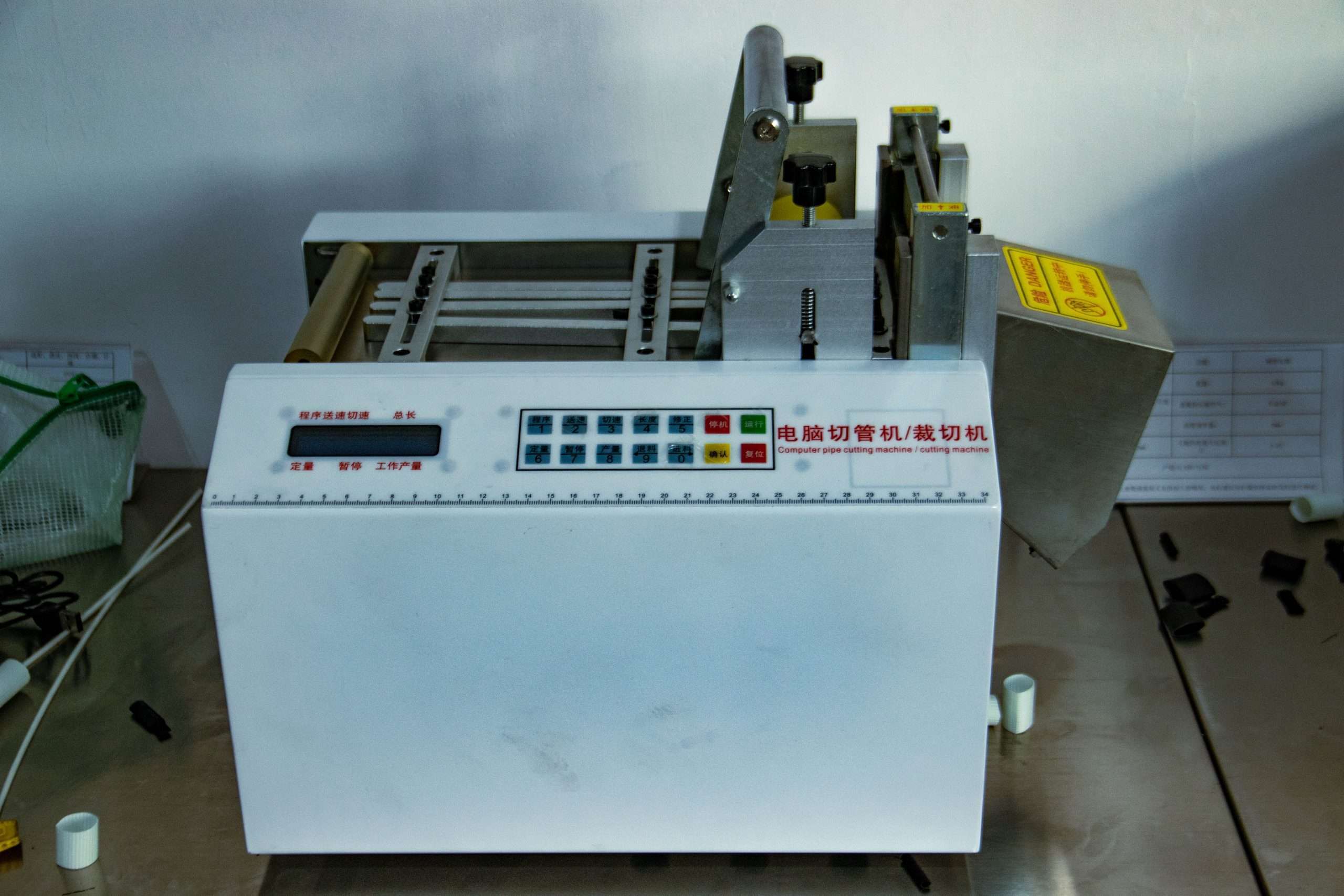

Automatic Plastic Tube Cutting Machine: An Engineer’s Perspective

After spending nearly a decade working in wire harness and tubing production, one lesson stands out: precision saves money, inconsistency costs money. A few years ago, when we were still cutting plastic and silicone tubes manually, we wasted hours dealing with uneven edges, rework, and frustrated assembly teams.

Switching to an automatic plastic tube cutting machine changed everything. Instead of debating whether a batch was “good enough,” we started trusting the numbers—every cut fell within tolerance, every time.

That’s why I believe this equipment isn’t just a “nice-to-have.” For medical tubing, automotive hoses, or even appliance drain lines, automation in cutting is now the backbone of competitive manufacturing.

What Exactly Is an Automatic Plastic Tube Cutting Machine?

Put simply, it’s a machine that takes in a coil of tube and delivers clean, burr-free pieces cut to your programmed length. It does the job a human operator can’t: repeat the same cut thousands of times a day with ±0.1mm accuracy.

In my own projects, I’ve run these machines on PVC, PU, nylon, and even silicone. Where manual cutting would often crush softer materials, the automated system feeds, clamps, and slices without deformation. And once you’ve programmed a batch, you can let the system run with minimal supervision.

Why Precision Matters

I remember one case from an automotive supplier we worked with. They needed fuel hoses cut for an engine project, and every millimeter mattered. Early on, hand-cutting created variations that caused leaks during testing. Once we switched them over to an automatic cutter, reject rates dropped to nearly zero.

That’s why precision in tube cutting isn’t just a technical detail—it directly impacts safety, compliance, and your reputation with customers.

Key Features I Rely On

Modern machines come with plenty of bells and whistles, but the features that actually make my life easier are:

Touchscreen programming: no more fiddling with dials or manual counters.

Servo-driven accuracy: once set, the length doesn’t drift.

Multi-material capability: I can run PVC in the morning, silicone in the afternoon.

Automatic feeding: instead of stopping every few minutes, the machine pulls the tubing itself.

If you’re curious about options, you can check our tube cutting machine lineup—we’ve built both standalone cutters and models integrated with chamfering or coiling.

Where These Machines Make the Biggest Difference

From my experience, the automatic plastic tube cutting machine shines in a few key industries:

Medical – One client producing IV lines saw their throughput jump by 30% after automating.

Automotive – Cooling and fuel lines cut with consistency, avoiding costly leak tests.

Appliances – Washing machine and dishwasher hoses, all cut to exact lengths for easy assembly.

General industry – Pneumatic tubing for factories where downtime is expensive.

For wire-related work, we often pair these systems with an automatic wire bending machine—that way, both wires and protective tubes are processed in the same production cell.

Automatic Cutting vs. Manual Cutting (Hard Truths)

When I compare the two, the difference is night and day:

| Feature | Automatic Machine | Manual Cutting |

|---|---|---|

| Speed | Hundreds per hour | Dozens per hour |

| Accuracy | ±0.1mm, consistent | Depends on operator |

| Waste | Minimal | High |

| Labor | One operator can run multiple machines | One operator tied to scissors or saw |

I’ve seen factories try to “save money” by sticking with manual methods, only to lose far more in scrap material and rejected parts.

How I Recommend Choosing the Right Model

Whenever I help a client choose a machine, we walk through a few questions:

What tubes are you cutting? PVC, silicone, reinforced hoses?

What tolerance matters to you? For medical, you might need ±0.05mm; for appliances, ±0.5mm may be enough.

What’s your production scale? Small batches or continuous 24/7 runs?

Do you need integration? For larger lines, connecting the cutter with an automatic crimping machine makes sense.

Answering these upfront usually avoids costly mismatches.

Looking Ahead

Automation in tube processing is only getting smarter. Some of the prototypes I’ve tested lately come with IoT monitoring, predictive maintenance alerts, and even AI-driven feed control. It’s exciting to see how far this industry is going—especially for factories aiming for zero-defect production.

FAQ

Q1: What materials can these machines handle?

I’ve personally used them on PVC, PU, silicone, and nylon. With the right blade, reinforced tubing works too.

Q2: Can one machine handle multiple tube sizes?

Yes—most models adjust clamps and feeders to switch between diameters.

Q3: How does it compare with an automatic wire bending machine?

Tube cutting handles the protective tubing, while the automatic wire bending machine takes care of shaping wires. Together, they form a solid automation combo.

Q4: Is it worth it for smaller factories?

Even a shop running just a few thousand cuts a day sees ROI quickly from reduced waste and labor savings.

Conclusion

As an engineer, I’ve seen firsthand how much frustration disappears once you move from manual cutting to an automatic plastic tube cutting machine. It’s not about replacing people—it’s about freeing them from repetitive work and ensuring every cut supports the bigger goal: reliable, scalable production.

If you’re considering the jump, think of it as an investment in both efficiency and peace of mind. In my experience, that’s worth far more than the upfront price tag.

7. Take Action Today

Ready to source from a reliable automatic crimping machine factory? Get a quote, request dual/triple-head demo, or explore our waterproof insertion models: