How to Choose the Best Automatic Terminal Crimping Machine in 2025: A Practical Buyer’s Guide

Choosing the right automatic terminal crimping machine might sound straightforward — but if you’ve worked in wire harness production, you know it’s anything but.

We’ve spent years testing machines on our own factory floor, helping clients from automotive to consumer electronics find solutions that actually deliver. In this guide, we’re sharing what we’ve learned — the good, the bad, and what to really watch for in 2025.

🔍 What Is an Automatic Terminal Crimping Machine?

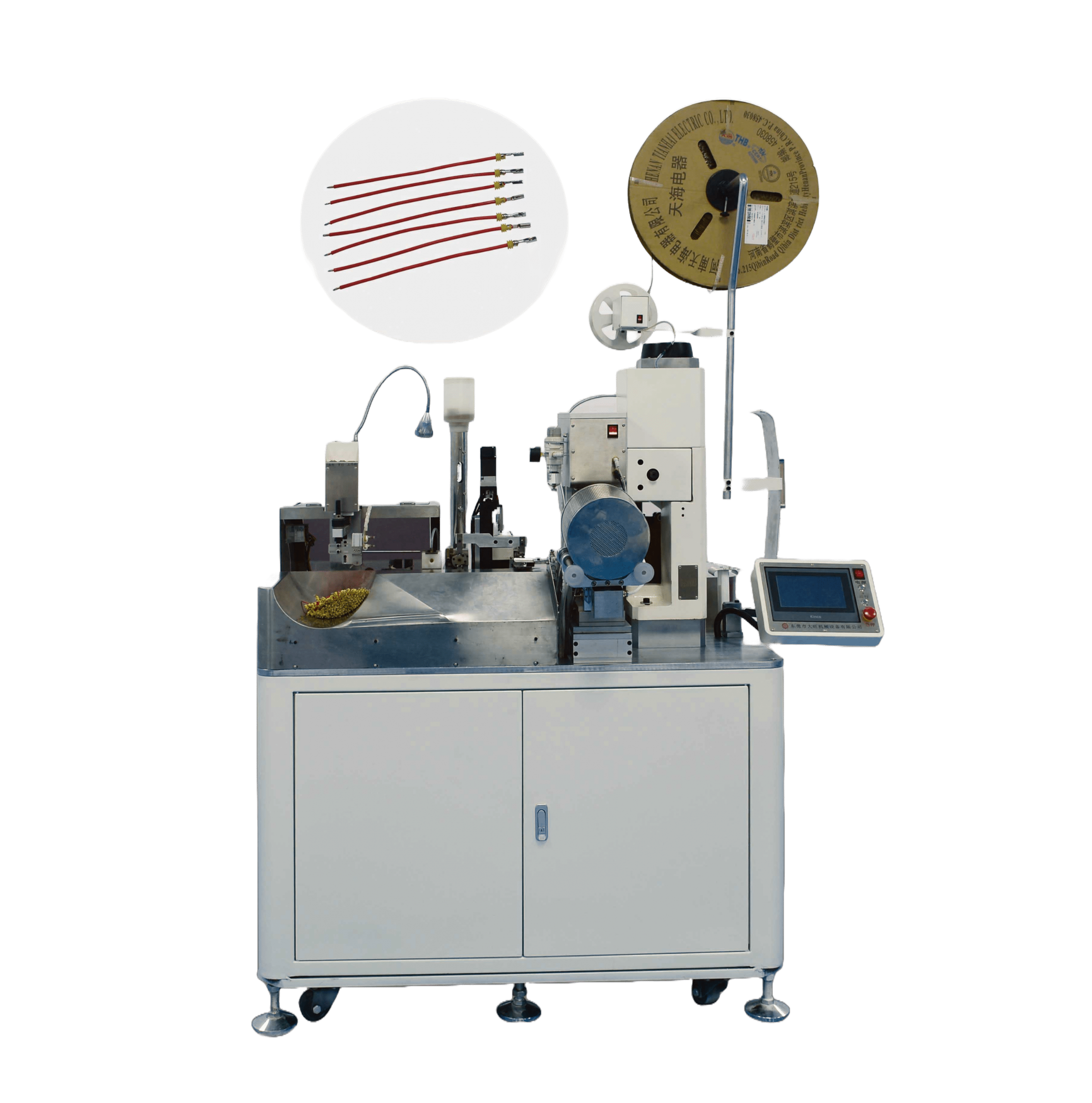

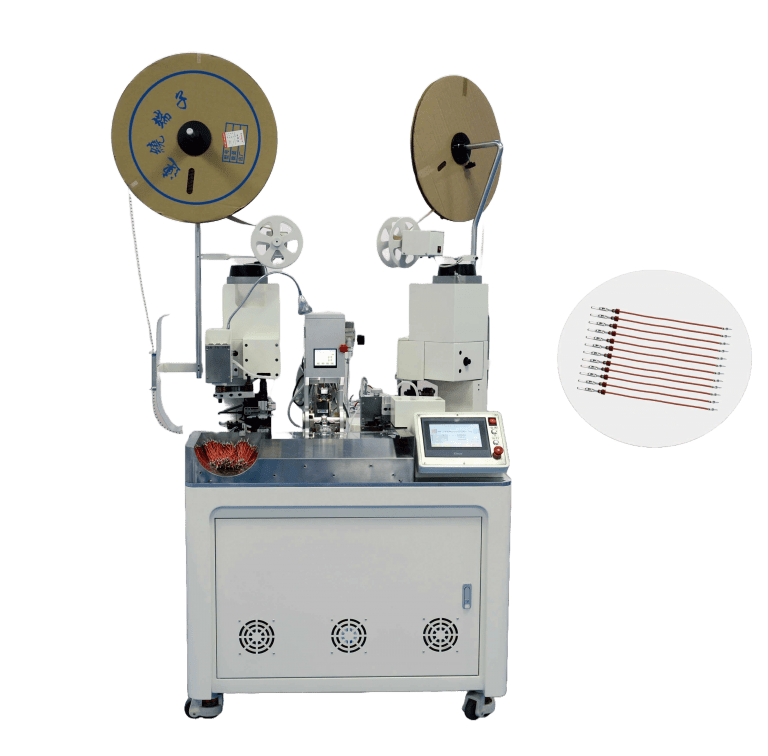

An automatic terminal crimping machine handles multiple wire-processing steps — cutting, stripping, and terminal crimping — in a single cycle. Some advanced machines (like our KKD6 model) even insert waterproof grommets as part of the process.

If you’re still manually crimping with handheld tools or semi-automated stations, the jump to full automation can be a game changer — but only if the machine fits your workflow.

🛠️ Types of Crimping Machines (and Why It Matters)

1. Handheld Tools – Great for Repairs, Not for Production

We’ve seen some small shops still using manual crimpers for batch work. They’re cheap, flexible, and fine for on-site repairs — but definitely not designed for consistency or speed.

2. Benchtop Semi-Automatic – A Useful Middle Ground

Benchtop machines are popular in mid-size factories. They often offer decent speed and reduce hand strain, but still require constant operator input. Accuracy can vary, and mistakes aren’t always caught until QA.

3. Fully Automatic – Built for Precision and Throughput

If you’re dealing with complex harnesses or need thousands of crimps per shift, full automation is worth the investment. Machines like the KKD3 can cut, strip, twist, and crimp both ends — hands-free.

👉 Here’s how our KKD3 model works in a real factory environment

🔧 How to Choose the Right Machine

Developed by a professional automatic crimping machine factory with years of industry experience. From our experience, here are 5 things every serious buyer should think about:

1. Wire Type and Terminal Style

Not all machines support the same range. Our KKD3, for example, handles AWG14–28 and continuous sheathed terminals. If you’re switching between wire sizes often, flexibility matters.

2. Production Volume

Estimate how many crimps you need daily or weekly. Machines like the KKD6 can handle up to 2800 pieces per hour for short wires, so match machine capacity to your demand.

3. Precision and Quality Control

A good crimp looks right — a great crimp tests right. Our automatic machines offer ±1mm + 0.2% cutting precision, crimp force detection, and fiber-optic wire sensors. These aren’t just features — they prevent scrap and recall.

4. Factory Layout and Workflow

Space and access matter. Full-size machines like the KKD series need air (4–6 kgf), stable power (AC220V), and operator clearance. You’ll also want to think about noise, maintenance access, and integration with your workbench.

5. Budget and ROI

Yes, automatic machines cost more upfront. But over a year, the savings in labor and rejects are massive. For many clients, they recoup the investment in under 12 months.

Comparing Popular Automatic Terminal Crimping Machines

| Feature | KKD3 / KKD6 Series | Other Machines |

|---|---|---|

| Processing Steps | Cut, strip, dual crimp, waterproof seal | Cut & crimp only |

| Max Output | Up to 2800 pcs/hour | 1200–2000 pcs/hour |

| Crimping Precision | ±1mm + 0.2% | ±0.5mm–1mm |

| Detection Systems | Fiber sensor, jam, crimp check | Basic error detection |

| Waterproof Seal Insertion | Yes (KKGSF2 model) | No |

| User Interface | Touchscreen, memory programs | Manual settings |

My Recommendation for 2025

If you’re looking for a reliable and efficient wire harness crimping machine in 2025, Whether in automotive wiring, consumer electronics, or industrial cabling, our role as an automatic crimping machine factory allows us to provide machines that fit diverse production needs. the KKD3 and KKGSF2 series stand out. These fully automatic terminal crimping machines deliver industry-leading precision, full automation, and options like waterproof grommet handling. They are especially suited for automotive wiring harness manufacturers, appliance cable producers, and industrial control panel makers.

Conclusion

Choosing the best automatic terminal crimping machine comes down to understanding your production volume, wire specifications, and required features. Fully automatic machines like the KKD series provide significant benefits in speed, accuracy, and flexibility — essential for businesses aiming to stay competitive in 2025 and beyond. Evaluate your needs carefully to make an informed purchase that maximizes your ROI.

📌 FAQs: What Buyers Usually Ask Us

Q: How hard is it to maintain an automatic crimping machine?

A: Surprisingly easy. Regular cleaning, checking blade wear, and following the onboard prompts is usually enough. We provide full manuals and video support.

Q: Can I switch wire sizes quickly?

A: Yes. Models like the KKD3 store up to 99 wire profiles. Switching setups takes minutes.

Q: Is this machine certified?

A: All models are built under ISO 9001 production standards. We test every unit before shipping.

Q: Do you manufacture these machines or just trade them?

A: We are a genuine automatic crimping machine factory, offering direct manufacturing, customization, and technical support for all crimping solutions.

📚 Read more about crimping standards and quality in wire harness production (Wikipedia)

📽️ See It in Action

Want to see how our machine runs in real conditions?

👉 Watch our latest demo on YouTube