A Technical Look at the Automatic Wire Processing Machine

Bottlenecks are the enemy on any production floor. When putting together wire harnesses, manual or semi-automated steps are often the main cause of slowdowns, quality issues, and wasted materials. The automatic wire processing machine is designed to fix this problem by handling the whole wire prep process in one system. It’s not just about going faster; it’s also about getting process control and repeatability that manual operations can’t match.

The automatic crimping machine is a common source of pain because a single bad crimp can cause a field failure. But the quality of the steps before it is what makes a crimp work. To make a really strong assembly, you need to think of the whole process as one wire harness automation line.

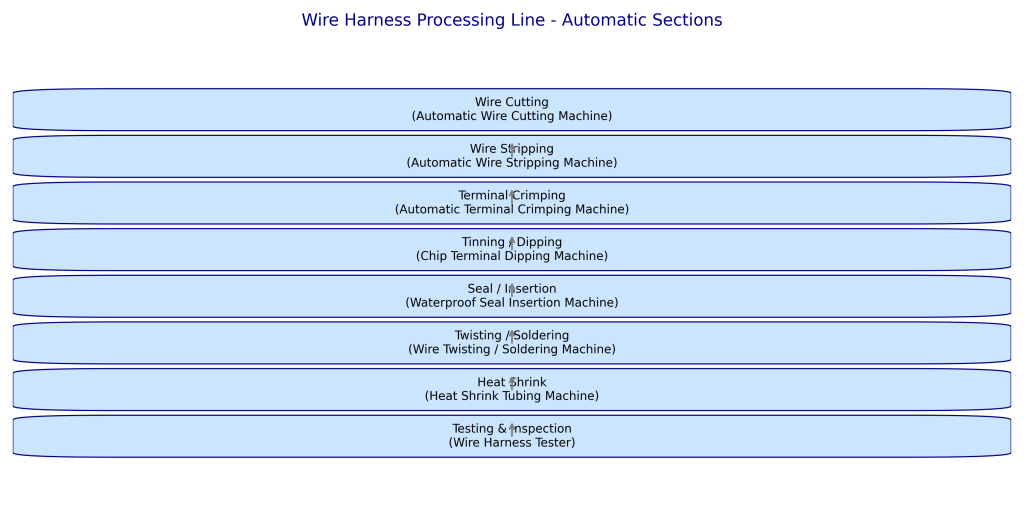

Breaking Down the Modular Wire Harness Automation Line

Think of a modern automatic wire processing machine not as a monolithic piece of equipment, but as a series of specialized, interconnected modules. Each automatic section is a dedicated unit designed for a specific task, allowing you to configure a line that meets the exact specs of your BOM (Bill of Materials). This modularity is key to building a system that solves your problems without paying for unnecessary capabilities.

Let’s examine the core modules.

Precision Starts Here: The Automatic Cutting Section

Every downstream process depends on getting the cut right. If your wire length is off, the termination point will be wrong.

Function: The automatic cutting section is the entry point, responsible for feeding wire from a spool and cutting it to a precise, programmable length.

Engineering Edge: High-resolution encoders and servo-driven feeders hit tight length tolerances (e.g., ±0.1mm), dramatically reducing scrap and ensuring every wire is identical. This unit provides the foundational accuracy for the subsequent automatic stripping section. For a deeper dive into industry standards for wire cutting, the IPC/WHMA-A-620 is the definitive guide for requirements and acceptance for cable and wire harness assemblies.

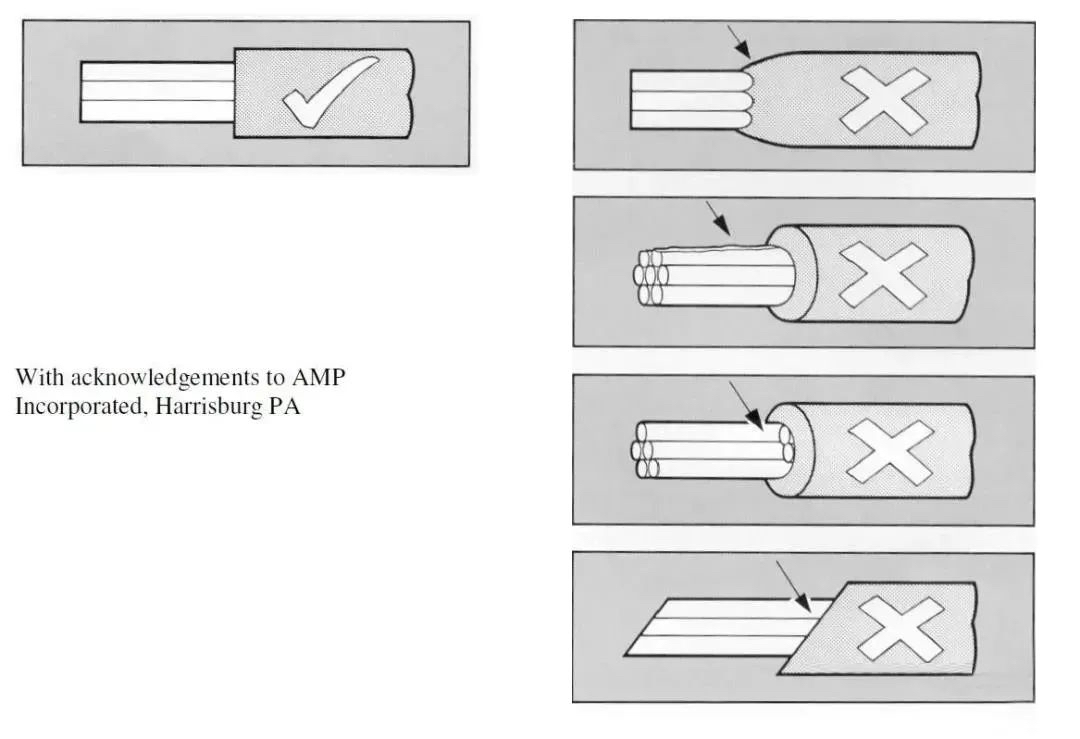

A bad strip—nicked conductors or insulation residue—is a common root cause of faulty connections. The automatic wire stripper module is designed to eliminate these variables.

Function: This automatic stripping section makes precise incisions and removes the insulation slug from the wire’s end, exposing the conductor.

Engineering Edge: V-blades and zero-cut capability ensure the stripping action never touches the copper strands. All parameters—strip length, pull-off distance, and blade depth—are programmable, giving you complete control over the quality of the strip for different wire gauges and insulation types. Explore our range of precision automatic wire stripping machines to find a solution for your application.

The Critical Connection: The Automatic Crimping Section

This is where the terminal and wire become one. The automatic crimping section is arguably the most critical module for long-term product reliability.

Function: An integrated automatic crimping machine press, fed by a specific applicator, forms and applies a terminal to the stripped wire end.

Engineering Edge: This is more than just a press. The real value is in the integrated Crimp Force Monitoring (CFM). The system analyzes the force-over-distance curve of every single crimp in real time. It instantly detects missing strands, incorrect insulation placement, or wrong wire gauge, flagging and rejecting a bad crimp before it ever gets into a harness. This is your first line of defense against field failures. The importance of this is underscored by research from organizations like SAE International, which publishes numerous standards on automotive crimping and terminal application. Our automatic terminal crimping machines are engineered with this precision in mind.

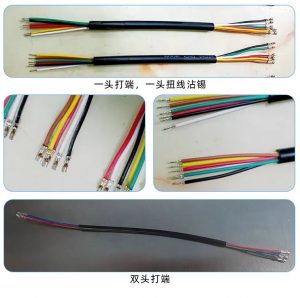

For Solder Applications: The Automatic Dipping Section

When your design specs call for a soldered connection instead of a crimp, tinning is essential for ensuring proper solder flow and preventing oxidation.

Function: The automatic dipping section applies flux and then dips the stripped wire ends into a molten solder pot, tinning them perfectly every time. This process is often engineered alongside a chip terminal dipping machine for specialized components.

Engineering Edge: Automating this process controls dip time, temperature, and depth, resulting in a consistent, high-quality solderable finish that manual methods can’t replicate. You can view our specialized automatic tinning machines here.

From Standalone Modules to a Fully Integrated Line

While each of these sections can operate as a standalone unit, the real efficiency gain comes from integrating them into a cohesive wire harness automation line. Modern wire harness automatic section equipment is built on a common control platform, allowing modules for sealing, twisting, doubling, or inkjet marking to be added as needed. For instance, a tape wrapping machine can be integrated for harness bundling.

This building-block approach allows you to design a machine that solves today’s production needs and can be expanded for future projects, providing a much stronger return on investment than fixed-function machinery.

Engineer's FAQ

Q1: We’re currently using a benchtop automatic wire stripper. What’s the real-world throughput gain of a fully integrated line?

A1: The primary gain isn’t just cycle speed; it’s the elimination of material handling between steps. With a benchtop automatic wire stripper, an operator has to batch the cut-and-stripped wires, move them, and then feed them into a separate crimper. A fully integrated line does this in one continuous motion. You’re not just getting faster cycles; you’re removing labor and potential for error from the entire workflow. This is a key principle of lean manufacturing, as often discussed by the Lean Enterprise Institute.

Q2: Our BOM uses several unique terminal types from different manufacturers. How difficult is it to re-tool a customized automatic section machine?

A2: This is a core design consideration for us. A customized automatic section machine is built around quick-change tooling. The crimping applicators, which are specific to each terminal, can typically be swapped out in minutes without special tools. All processing parameters for that specific job—wire length, strip dimensions, crimp height—are stored as a program, so changeover is fast, repeatable, and requires minimal operator adjustment. Our programmable wire cutting machines are a part of this flexible system.

Q3: We have to meet stringent UL and SAE quality standards. How does the automatic crimping machine section help with validation and documentation?

A3: The Crimp Force Monitoring (CFM) system is essential for this. It provides 100% inspection and creates a data log for traceability. You can prove that every crimp on a job was made within your pre-validated force specification. This moves you from batch-level destructive pull-testing to continuous, non-destructive monitoring, giving you the data you need to satisfy internal quality requirements and external audits.

Talk to us

Have a specific application or a challenging component? Let’s talk specs. We can help you configure a system that meets your performance and quality targets.