Meet the KK510, the relentless engineer working for your workshop. This belt-driven automatic wire stripper carries out industrial-scale cutting (99,999.9 mm) with the accuracy of surgery (0.1–250mm stripping). Its one hundred-plus-programme memory helps to retain production knowledge, and a seven-inch touchscreen runs operations with the dexterity of a seasoned maestro. The hybrid stepper motor will effortlessly create error-free works of art whether it’s disassembling USB connections or vehicle wiring. By using automated wire feeding and support for multiple languages, complex activities can be converted into seamless processes, therefore changing technology into a kind of handcraft.

Watch the Production Lines (Video Demo)

Key Features of the Automatic Wire Stripper

- Surgical Stripping Accuracy

- Dual-end stripping (0.1-250mm front / 0.1-100mm rear) with tungsten steel blades for clean, fray-free cuts on wires up to 70mm².

- Giant-Scale Cutting Capacity

- Process wires up to 99,999.9mm (328ft) – ideal for automotive harnesses or renewable energy cable projects.

- 32-Bit Brain with Muscle

- Hybrid stepper motor + caterpillar belt drive ensures zero length deviation at 200 cuts/min (max), even in 24/7 operations.

- Smart Production Partner

- 7″ multilingual touchscreen stores 100 wire profiles – switch between USB data cables and armored power cords in 3 taps.

- Self-Correcting Workflow

- Auto wire feed/jam detection + real-time alerts minimize downtime. Add the optional knurled rubber rollers for delicate flat wires.

cablemachineries.com

Made for engineers who won’t compromise, the KK510 redefines wire processing with industrial-grade dependability and simple intelligence. Its 32-bit microprocessor manages wires from hair-thin 0.1mm data cables to tough 70mm² power lines, and hybrid stepper motors drive caterpillar belts with micron-level accuracy.

Not only is the 7-inch multilingual touchscreen an interface; it’s your production archive, saving 100 wire profiles to quickly reconfigure operations between smart device assembly, solar farm connections, or car harnesses. See perfect engineering used in every specification: Equivalent to 328 feet, 0.1–250mm front stripping coupled with 99,999.9mm maximum cuts lets you confidently handle aerospace projects and EV battery lines.

While heat-treated rollers change grip pressure to safeguard fragile wires, tungsten steel blades sharpened to surgical standards cleanly separate insulation. Smart diagnostics take front stage when manufacturing scales: automatic feed systems stop jams, real-time alarms indicate anomalies, and batch scheduling keeps your workshop running through third shifts.

It’s your strategic edge, more than just a machine—blending nimble software logic with German mechanical discipline. Optional rubberized rollers show why worldwide manufacturers trust the KK510 to take perfection from a promise into measurable ROI: they extend their mastery to flat wires. Because in wire processing every millimeter defines quality.

Applications of Automatic Wire Stripper KK-510

- Automotive Wiring Harnesses

Processes thick-gauge EV battery cables (up to 70mm²) and delicate sensor wires with zero length deviation. - Renewable Energy Systems

Handles solar/wind farm power cables and junction box assemblies requiring 99,999.9mm ultra-long cuts. - Consumer Electronics

Precision-strips USB-C, HDMI, and micro-coaxial cables for smartphones and IoT devices. - Aerospace & Defense

Terminates shielded MIL-SPEC wires and high-temperature aircraft cables without conductor damage. - Smart Home & Appliances

Processes flat ribbon cables for smart switches and appliance control panels. - Medical Equipment

Ensures burr-free stripping for life-critical diagnostic device wires (0.1mm precision). - Industrial Automation

Prepares motor control cables and robotic arm wiring with batch-mode efficiency.

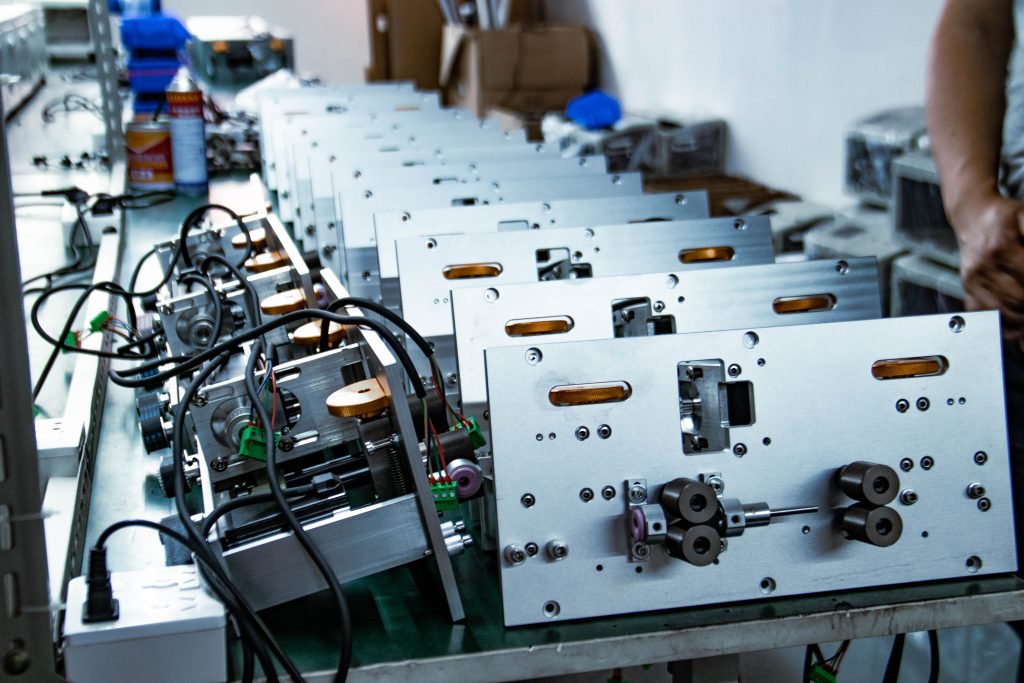

Product Introduction | Fully Automatic Computerized Wire Stripping Machine (Belt-Driven Type) |

Model Number | KK510 |

Overall Dimensions | 930mm(L)× 420mm(W)× 370mm(H) |

Weight | 105kg |

Display Type | 7-inch touchscreen |

Power Input | AC220V/50-60Hz |

Mainboard | Motion control card |

Cutting Length Range | 0.1mm—99999.9mm |

Stripping Length Capacity | Front Stripping 0.1–250mm, Rear Stripping 0.1–100mm |

Wire Cutting Range | Outer diameter ≤20mm, cross-sectional area ≤70mm |

Cutting Length Adjustment | Stepless adjustment |

Motor | Hybrid stepper motor |

Conduit Diameter | Ø4 Ø8 Ø10 Ø12 |

Blade Material | Tungsten steel / Imported high-speed steel |

Wire Feeding Rollers | Heat-treated iron rollers / Knurled rubber rollers |

Drive Mechanism | Caterpillar drive (belt-driven) |

Wire Pressure Control | yes |

Automation Features | Auto Wire Feeding/Ejection, Scheduled Start |