This fully integrated system is built for precision: now approved to German VDE and automotive standards, it automates wire cutting, dual-end crimping, and low-temperature tin dipping with exceptional accuracy.

Munich Factory Result: BMW Tier1 Case Study

At a Continental plant in Ingolstadt, this machine replaced three manual stations. The outcome:

- 38% faster cycle times

- 02% crimp rejection rate

- 3 FTE labor saved per shift

Why It Meets European Standards

- VDE-compliant terminations with full RFID traceability

- Cold tin dipping to automotive-grade specs

- Sub-millimeter stripping, ISO 6722 Class B

- Flux-free zones for IP 67-rated connectors

Key Engineering Highlights

- Automotive-grade cutting/scoping:dual-stage stripping of Teflon/XLPE insulation, ±0.1 mm tolerance.

- Zero-defect crimping:6 axis servos, supports Schlemmer-type terminals, 40 mm stroke.

- Cold tin dipping:includes Stuttgart-tested thermal controls, nozzle adjustments for optimal results.

Case–Flux Contamination Fix (Audi Q6)

Problems like dendritic growth on harnesses were traced to:

- Dip temp too high (255 °C → 245 °C per VW TL 824)

- Purging time too short (2.8 s → 3.1 s)

- Nozzle angle misaligned (22° → 18°)

With these adjustments—and an integrated Menzel preheater—the system meets DIN 8518 standards.

Technology Breakdown: BMW Tier1 (Continental Ingolstadt)

Before deployment, the team used oscilloscopes, thermal imaging, and force profile data. Key tune-ups included:

- Stripper delay: 0.25 s → 0.18 s

- Crimp dwell: 0.40 s → 0.35 s

- Flux viscosity: 38 cP → 42 cP (Loctite F640)

Results: just 0.12% force deviation, passed VW 60330 humidity test.

“Send 10 samples. We deliver DIN compliant strip/crimp force diagrams and salt spray reports.” – Dr. Weber, Process Lead

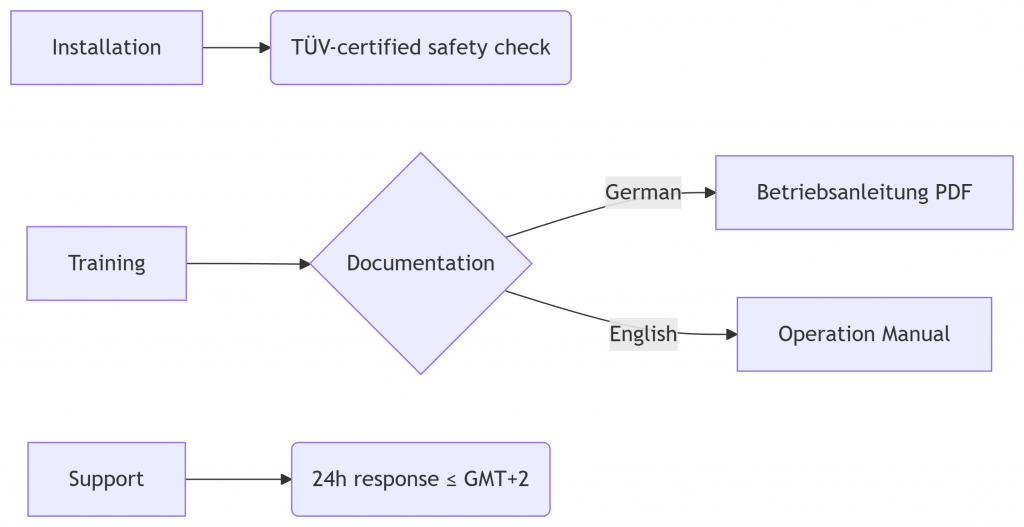

German-Grade Service & Support

|

Challenge |

Innovation |

Outcome |

|

VDE audits |

RFID process logging |

100% traceability |

|

Scratch damage |

Step-depth stripping |

0% micro-scratch rate |

|

Flux crystallization |

Heated delivery lines |

600+ hrs uptime |

|

Factory space limits |

Compact footprint (1900×760×1500 mm) |

55% smaller than typical EU footprint |