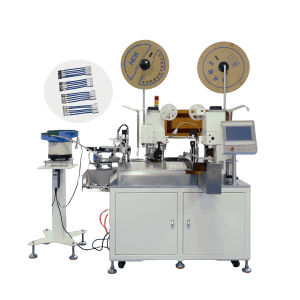

Automatic Wire Strippers for Industrial Applications

In an era where a single faulty connector can halt automotive assembly lines costing $22,000/minute (per Automotive News research), selecting a certified automatic crimping machine factory becomes strategic. At CableMachineries, we engineer crimping systems that achieve 99.98% first-pass yield rates – transforming wire processing from cost center to competitive advantage.

Introduction: Why Wire Stripping Automation Matters

In today’s industrial manufacturing environment, speed, accuracy, and reliability are no longer optional—they define competitiveness. Wire processing, often considered a small step in the production chain, has become one of the most critical areas of optimization. From automotive harness assembly to renewable energy cable production, wire stripping quality directly impacts safety, efficiency, and long-term reliability.

In North America, where labor costs are high and productivity is closely monitored, companies are increasingly turning to automatic wire strippers to reduce error rates, minimize manual labor, and maintain compliance with stringent quality standards such as IPC/WHMA-A-620.

This guide provides a comprehensive overview of wire stripper machines: how they work, their advantages over manual tools, the key features to look for, and practical buyer’s tips. Along the way, we will compare different stripping technologies and show why the best automatic wire stripper solutions are transforming modern factories.

What is an Automatic Wire Stripper?

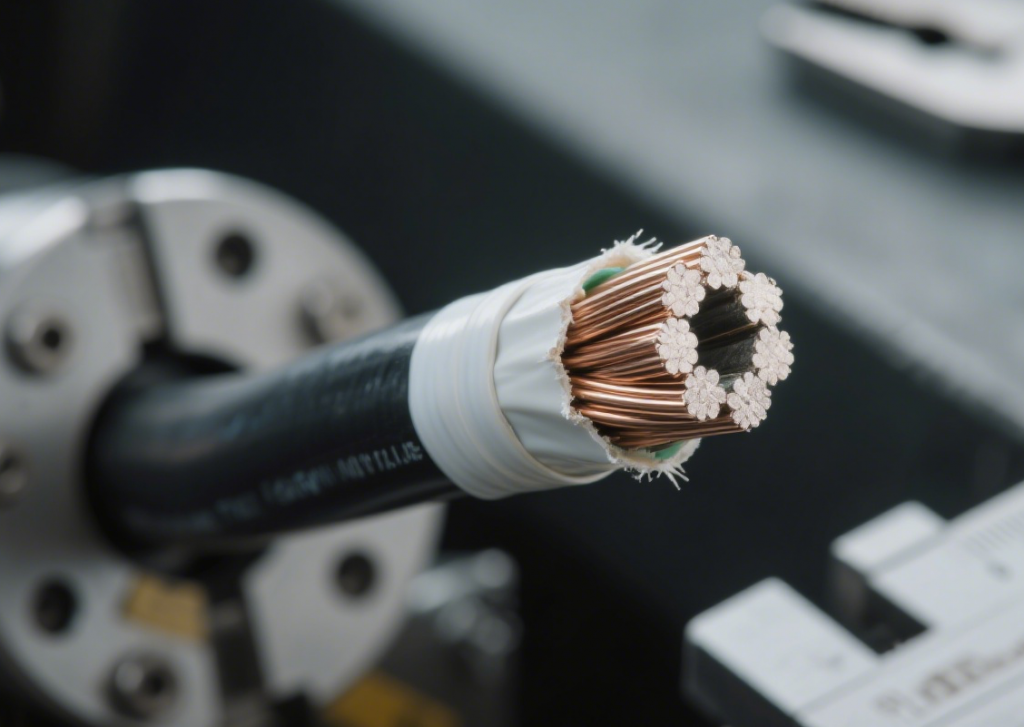

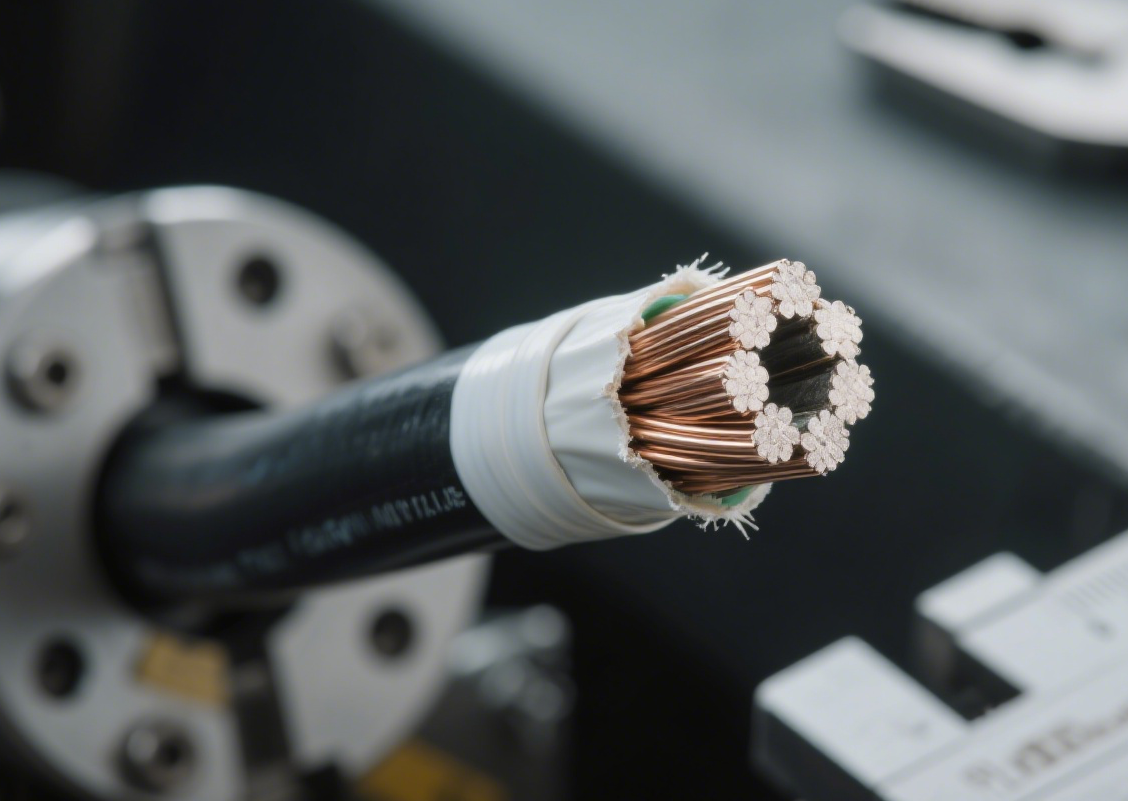

A wire stripper is a tool or machine designed to remove insulation from electrical wires without damaging the metal conductor inside.

Manual wire strippers resemble pliers with adjustable jaws, depending entirely on operator skill.

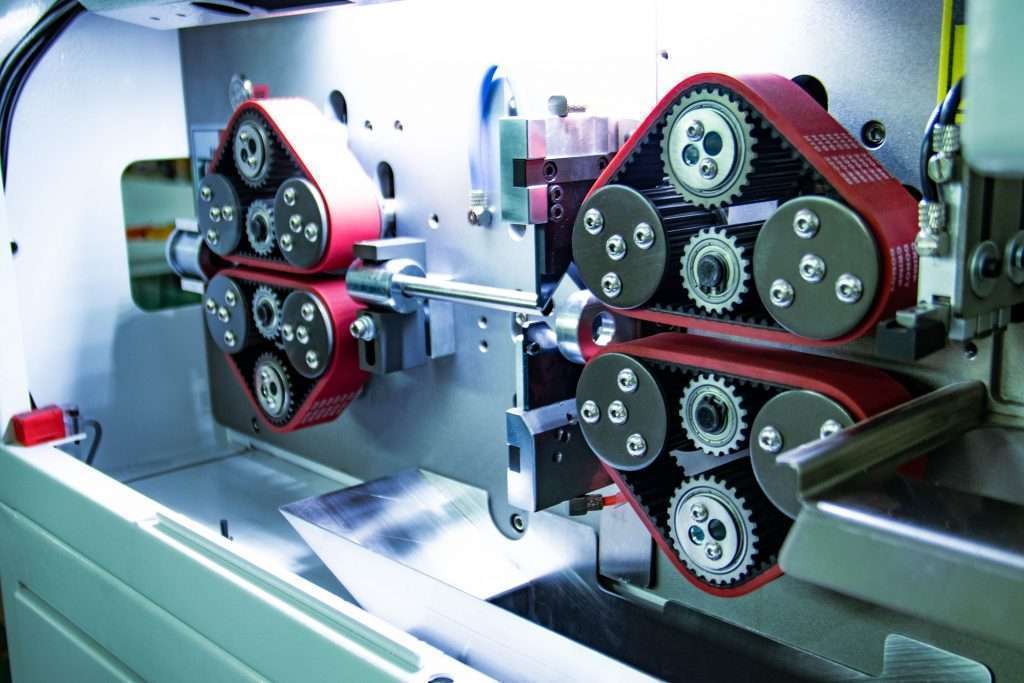

Automatic wire stripping machines go far beyond. They integrate programmable controls, servo-driven blades, and precision sensors to strip wires consistently with tolerances as fine as ±0.1 mm.

Advanced models can process:

Coaxial cables

Multi-layer insulation wires

Heavy-duty wires up to 4 AWG or 6 AWG

These capabilities make them invaluable in high-volume industrial operations, where accuracy and repeatability are essential.

In essence, automatic wire strippers combine speed + consistency, making them the backbone of aerospace cabling, EV charging station wiring, and industrial harness production.

Manual vs. Semi-Automatic vs. Automatic Wire Strippers

Choosing between manual, semi-automatic, and automatic wire strippers depends on production scale.

Manual Wire Stripper Tool

Cost: $10–$50

Throughput: ~200 wires/hour (operator-dependent)

Use Case: Electricians, field technicians, small workshops.

Semi-Automatic Wire Stripper

Cost: $500–$2,000

Throughput: ~600–1,000 wires/hour

Use Case: Repair shops, medium-scale pilot lines.

Automatic Wire Stripper Machine

Cost: $5,000+ (industrial-grade)

Throughput: 2,000–5,000 wires/hour

Extra Functions: Stripping, cutting, crimping, twisting.

Case Study

A Michigan-based automotive supplier reported a 37% reduction in production time after switching from semi-automatic tools to a fully automatic wire stripper, achieving ROI within months.

Key Features of the Best Automatic Wire Strippers

When evaluating industrial wire stripper machines, procurement teams should focus on measurable features:

Precision Control

Servo-driven motors and adjustable depth settings prevent copper strand damage.

Multi-Layer Stripping

Ability to strip coaxial, shielded, and Teflon-coated wires.

Integrated Functions

Some models combine stripping, cutting, and terminal crimping in one cycle, reducing machine footprint.

👉 See also: Terminal Crimping Machines

Heavy-Duty Compatibility

Support for large-diameter power cables (4 AWG, 6 AWG, 30 mm²).

User-Friendly Interface

Touchscreen controls with memory storage for multiple wire profiles.

Durability & Maintenance

Self-calibrating systems and hardened steel blades extend service life.

Applications

Automatic wire strippers are now standard in industries where wiring integrity = safety + performance:

Automotive Harness Production – EV and hybrid vehicles require precision crimping and stripping.

Renewable Energy – Solar farms and wind turbines rely on heavy-duty cable strippers.

Aerospace & Defense – Compliance with FAA and military wiring standards.

Telecommunications – Coaxial cable strippers for high-frequency networks.

Construction & Infrastructure – Adjustable wire strippers for varied site installations.

5. Industry-Specific Solutions

Choosing the Best Automatic Wire Stripper: A Buyer’s Guide

When selecting a machine, consider:

Wire Range & Capacity

Can it handle both fine signal wires and heavy-duty power cables?

Throughput Requirements

Match stripping speed with production goals.

Integration Potential

Look for models that combine cutting, stripping, and crimping.

Cost vs. ROI

Factor in labor savings, reduced scrap, and fewer reworks.

After-Sales Support

North American buyers often prefer suppliers with localized service, quick spare part availability, and training programs.

👉 Cable Machineries provides regional support for both wire stripping machines and terminal crimping machines.

ROI and Productivity Gains

Investing in an automatic wire stripper machine pays back quickly:

Labor Savings – One operator can run multiple machines simultaneously.

Quality Assurance – Consistent stripping = fewer defects and returns.

Material Savings – Less copper waste thanks to precision blades.

Scalability – Expand production with modular add-ons.

📈 Example: A facility processing 10,000 cables/day saved $80,000 annually by moving from manual tools to automated wire strippers.

Industry Trends and Future Outlook

Transparent pricing, fast quotation process

Free remote setup assistance + video training

Custom crimp settings for various terminal types

Strong export track record in EU, South America, and Southeast Asia

At CableMachineries, we’re more than just a supplier—we’re your automation partner. Here’s what makes us a standout automatic crimping machine factory:

Conclusion: Moving Toward Smarter Wire Processing

The automatic wire stripper has evolved from a simple convenience to an industrial necessity. From aerospace wiring to solar energy infrastructure, it ensures consistency, safety, and cost efficiency.

Whether you are looking for:

A multi-function wire stripper crimper

A heavy-duty industrial wire stripping machine

Or a scalable automation solution

…the right choice will keep your facility competitive.

Procurement managers should evaluate precision, reliability, and after-sales support, not just upfront price.

👉 Explore related solutions: Terminal Crimping Machines

By aligning with trusted suppliers like cablemachineries, North American manufacturers can achieve both technical excellence and peace of mind.

图2-298x300.png)