Introduction: Why Precision Matters in Cable Processing

In today’s competitive manufacturing landscape, every second counts. Whether you’re assembling high-frequency RF systems for aerospace, wiring up broadcast equipment, or producing telecommunication infrastructure, the quality of your cable preparation can make or break your end product. That’s where a coaxial cable stripping machine comes in — delivering unmatched precision, consistency, and speed.

Manual cable stripping is not only time-consuming but prone to errors. A single uneven cut can damage expensive coaxial cables, leading to waste, rework, and higher production costs. With a dedicated coax stripping machine, you can eliminate guesswork, standardize results, and dramatically improve throughput.

Understanding Coaxial Cable Stripping

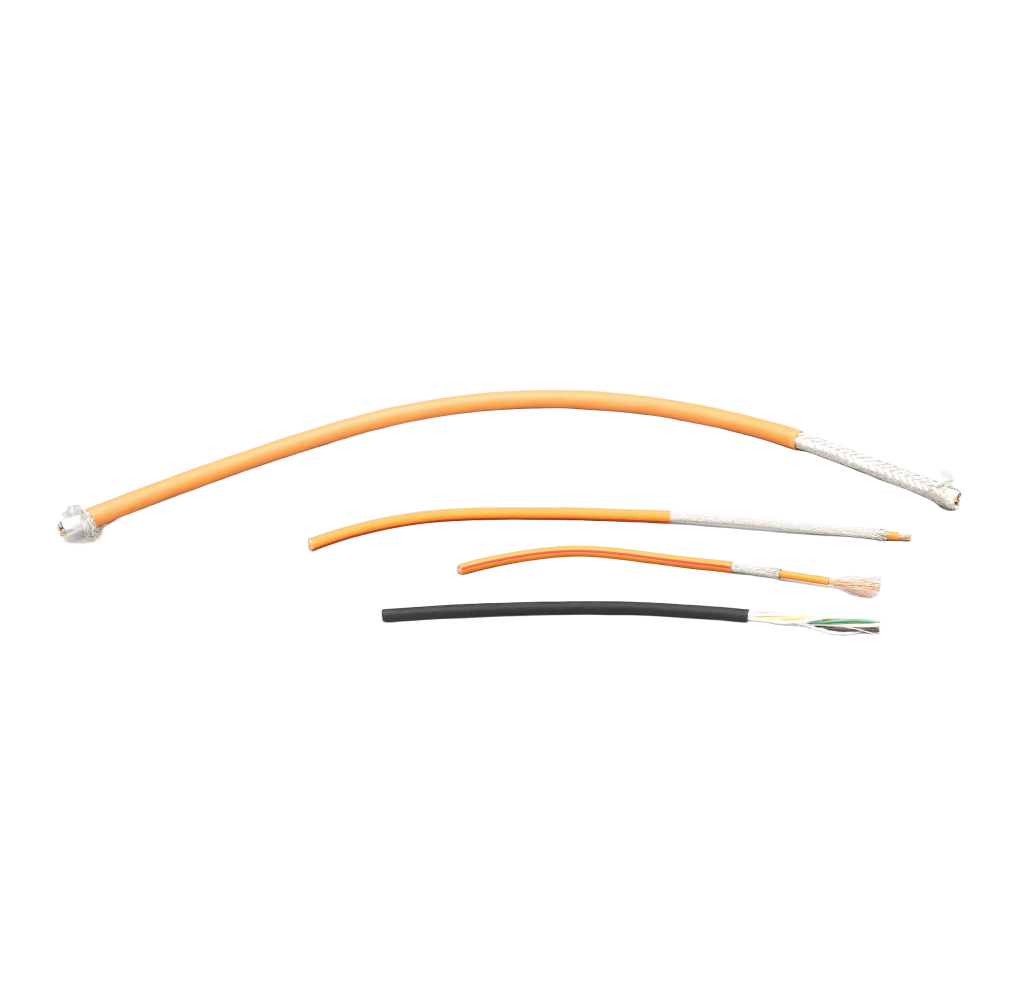

Coaxial cables are designed with multiple layers — each serving a critical purpose in signal transmission and shielding. Stripping them requires carefully removing the insulation without nicking the conductor or damaging the shielding. This process becomes more complex when dealing with Multilayer Stripping, where different insulation materials and diameters need to be removed in a precise sequence.

Traditional methods often rely on handheld tools, but these cannot match the repeatable accuracy and speed of a professional-grade coaxial wire stripping system. By automating the process, you not only improve quality control but also reduce labor strain and operational downtime.

Product Overview: Advanced Multilayer Stripping Technology

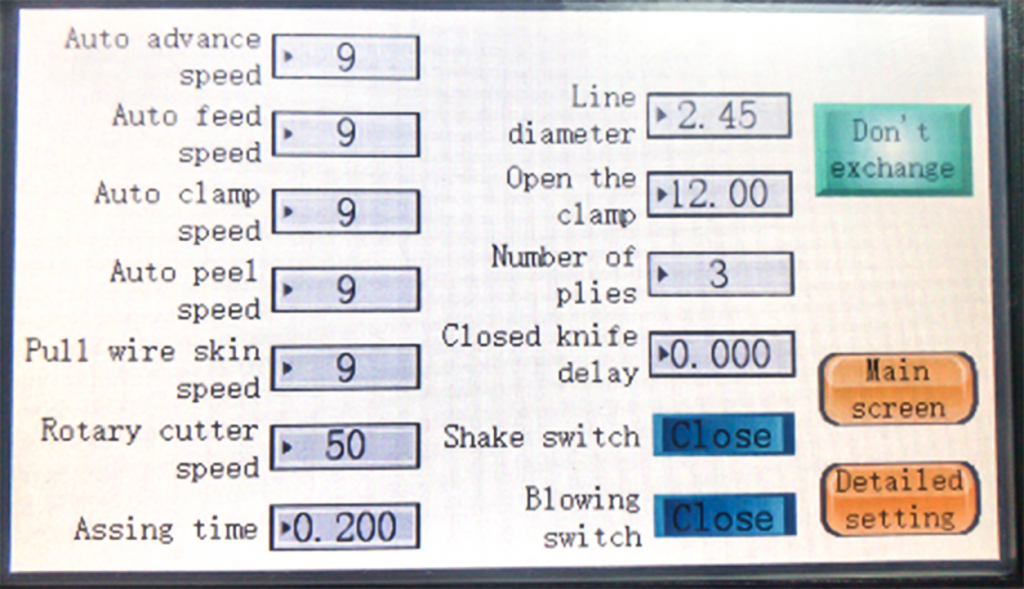

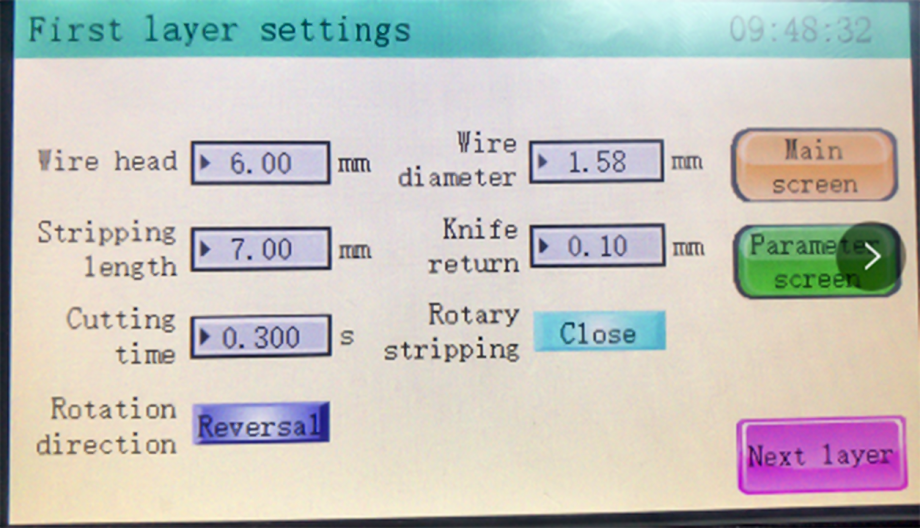

Our coaxial cable stripping machine at cablemachineries is engineered to meet the demanding requirements of manufacturing facilities. Built with advanced control systems, it supports multi-layer stripping for coaxial cables, allowing you to program each layer’s stripping length, blade return time, cut-off time, and rotational peeling.

The key advantage? You can tailor the machine’s operation to match different cable specifications, ensuring a perfect strip every time. Whether you’re working with semi-rigid coax for defense applications or flexible coax for broadcast setups, this machine adapts to your needs.

Technical Parameters at a Glance

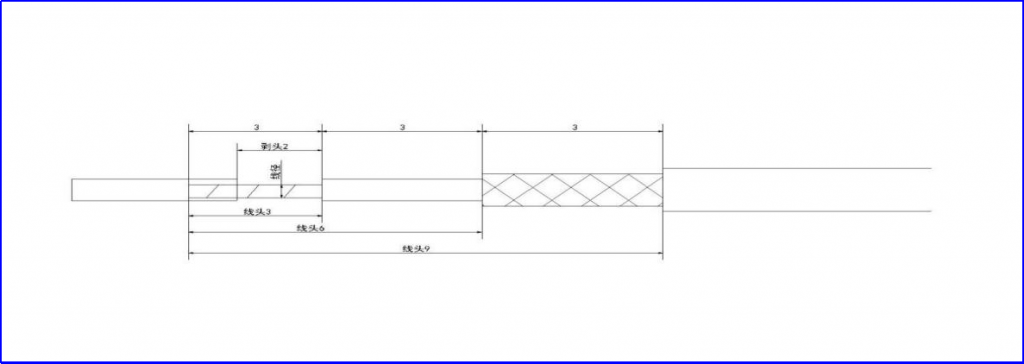

| Layer | Thread End (mm) | Peel Off Head (mm) | Wire Diameter (mm) | Return Knife (sec) | Cut Off Time (sec) | Spin Peeling (sec) |

|---|---|---|---|---|---|---|

| First Layer | 6 | 7 | 0.6 | 0.1 | 0.2 | 0 |

| Second Layer | 3 | 2 | 0.3 | 0.1 | 0.2 | 0 |

| Third Layer | 9 | 10 | 0.9 | 0.1 | 0.2 | 0 |

Each of these parameters can be adjusted to fit your exact production needs. This flexibility is a major advantage for companies handling a variety of cable types and configurations.

How It Works: Streamlined Stripping Sequences

Operating the machine is straightforward yet highly customizable:

Set your stripping lengths for each layer — for example, 6 mm for the first layer, 3 mm for the second, and 9 mm for the third.

The machine follows the programmed path (e.g., 6 → 3 → 9) and automatically returns to the start position.

You can reorder sequences (e.g., 3 → 6 → 9 or 9 → 3 → 6) for different cable constructions.

For cables with more than three layers, additional settings screens let you fine-tune each layer.

Once programmed, return to the main screen, press Reset, and the machine is ready to work.

This automation ensures consistent results, reduces the chance of human error, and frees up skilled labor for higher-value tasks.

Key Features and Benefits

Multi-Layer Stripping Capability – Handle complex coaxial cables with ease.

Adjustable Stripping Path – Optimize the sequence for maximum efficiency.

Precision Blade Control – Prevent conductor nicks and ensure clean cuts.

Support for Multiple Cable Diameters – From small coax to larger specialty cables.

User-Friendly Interface – Quick setup, minimal training required.

Repeatable Accuracy – Perfect for high-volume production environments.

For manufacturers, this means fewer production delays, less waste, and higher customer satisfaction.

Warranty and Service You Can Trust

We understand that downtime is costly. That’s why our machines come with a one-year warranty from the purchase date. While consumables such as blades, hex wrenches, foot switches, power cords, springs, and belts are excluded, our service team is ready to keep your equipment running at peak performance.

Exclusions include:

Damage from natural disasters

Faults caused by incorrect operation

Unauthorized disassembly or repair

Use of non-original consumables

Operation with incorrect voltage

To make servicing easier, always keep your warranty card and original purchase receipt.

Applications Across Industries

The coax stripping machine is ideal for a wide range of North American industries:

Telecommunications – Preparing coax for high-speed internet and network installations.

Broadcast & Media – Stripping cables for video transmission systems.

Aerospace & Defense – Meeting strict standards for signal reliability.

Electronics Manufacturing – Ensuring clean cable prep for assembly lines.

By integrating this machine into your production line, you’re investing in consistency, compliance, and customer confidence.

Why This Machine Outperforms Manual Methods

Let’s face it — manual coaxial wire stripping is not scalable. Labor costs are high, and skilled technicians are in demand. Automating this task:

Cuts labor costs by reducing manual work hours.

Prevents costly rework from human error.

Boosts throughput without sacrificing quality.

When you multiply these benefits across thousands of cables per month, the return on investment becomes clear.

Conclusion: Upgrade Your Cable Processing Today

In a market where precision, speed, and reliability define success, investing in a coaxial cable stripping machine is a smart move. With its advanced Multilayer Stripping capabilities, customizable operation, and robust build quality, this machine delivers the performance manufacturers demand.

Stop losing time to inconsistent manual stripping. Upgrade to automation, and experience faster turnaround, lower costs, and better product quality.

Contact us today to learn how the right coax stripping machine can transform your cable production process.