Heavy Duty Wire Stripper — Techniques for 4–6 AWG Cables

In modern industry, handling large-gauge cables such as 4–6 AWG is a persistent challenge. From DC connections in renewable energy plants to high-voltage wiring in EV charging stations, the quality of wire stripping directly determines safety, reliability, and efficiency.

Manual stripping is not only slow but also risks damaging conductors, which may cause resistance increase, overheating, and costly failures at connection points.

Why Large-Gauge Cable Stripping Is So Challenging

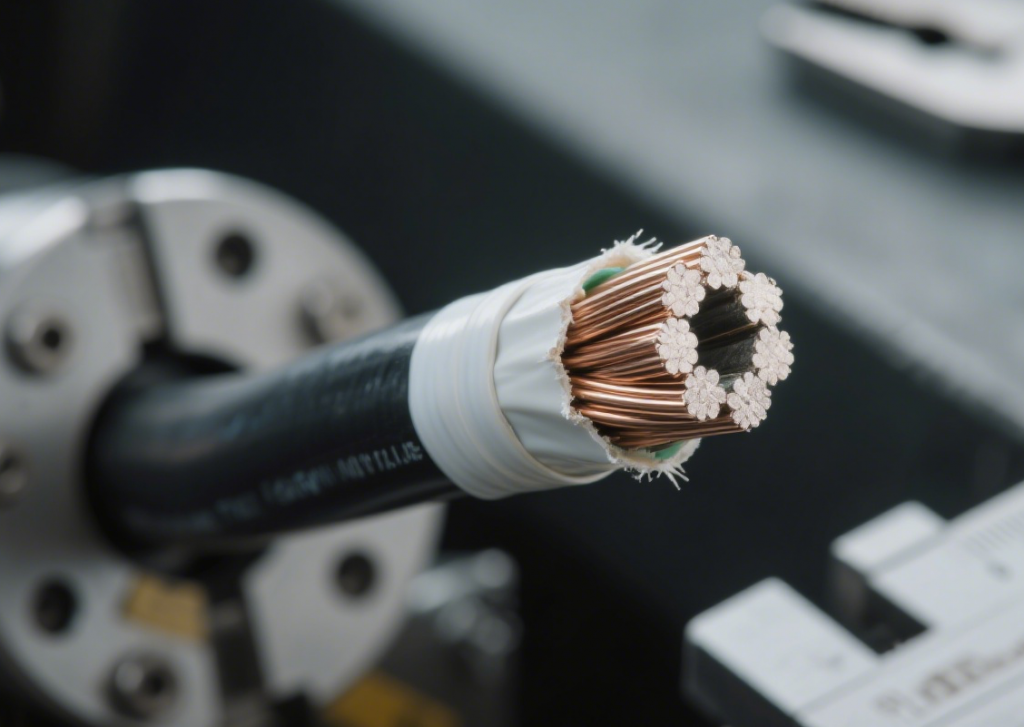

Processing 4–6 AWG cables (≈21.2–13.3 mm² cross-section) is far from simple. These heavy-duty cables are essential for high-current applications, yet they present several difficulties:

Insulation Rebound

Thick PVC or XLPE insulation is elastic. After cutting with a standard blade, the material often springs back, leaving incomplete cuts and extra material.Conductor Damage Risk

Even minor scratches on copper increase resistance and may lead to localized overheating. Manual stripping has been shown to cause up to 20% conductor deformation.Operator Fatigue

Stripping large cables by hand requires considerable force, leading to fatigue and inconsistent results.

Engineering Solutions with Professional Equipment

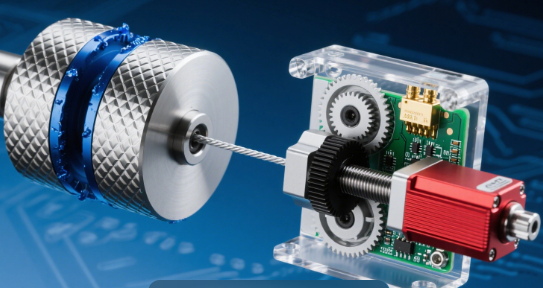

图1-995x1024.png)

To overcome these challenges, modern automatic wire stripper machines integrate advanced technologies that ensure precision, repeatability, and safety.

1. Dual V-Blade Design

By applying balanced force from two angles, V-shaped blades cut cleanly through insulation without damaging copper conductors.

Example: Weidmüller’s Stripax 16 handles cables up to 16 mm² for both solid and stranded wires.

2. Adaptive Pressure Control

Automatic pressure adjustment (0–50 kg) adapts dynamically to different insulation materials, whether PVC, XLPE, or composite jackets. This reduces downtime and recalibration.

3. Multi-Layer Stripping Capability

Many industrial cables include shielding, braiding, or double insulation. Programmable strippers such as the Komax UniStrip 2600 handle multiple layers with precision stripping lengths of up to 80 mm.

Applications Across Industries

Renewable Energy

In solar power systems, 4–6 AWG cables link modules, inverters, and combiner boxes. Proper stripping ensures low resistance and stable long-term performance.EV Charging Infrastructure

High-current charging stations demand precise stripping. Automated tools improve consistency, safety, and throughput.Aerospace & Defense

These sectors demand the highest precision—microscopic conductor damage is unacceptable. Professional equipment provides reliable, repeatable results.

Technical Specifications

| Feature | Specification Range |

|---|---|

| Cable Capacity | 0.5 mm² – 16 mm² (up to 4–6 AWG) |

| Stripping Length | 6–40 mm |

| Multi-Layer Capability | Yes (shielded and coaxial) |

| Precision | ±0.1 mm |

| Power Requirements | AC 220V, 50/60 Hz |

Our Wire Stripping Machine Solutions

At CableMachineries, we design automatic wire stripper machines tailored to handle a wide range of industrial needs, including large-gauge wires like 4–6 AWG.

Example Product: KK-501 Dual-Wire Computerized Stripping Machine

Cable Size Range: 0.1–2.5 mm², supports two wires stripped simultaneously (AWG32#–18#).

Stripping Capability: Up to 13 intermediate stripping segments, front stripping up to 50 mm, rear stripping up to 30 mm.

Precision: ±0.05 mm/m tolerance with 0.03 mm blade accuracy.

Efficiency: 3,000–5,000 dual wires per hour with optional auto-break detection.

Applications: Ideal for wire harness manufacturers and automation labs.

This machine is especially effective for small-to-medium gauge wires, but its precision demonstrates the engineering standards applied across our product line.

Choosing the Right Wire Stripper Tool

When selecting a wire stripper machine, consider:

Cable Range – Does it cover both fine wires and large-gauge conductors like 4–6 AWG?

Production Speed – Semi-automatic machines strip 600–1,000 cables/hr; fully automated models can reach 2,000–5,000 cables/hr.

System Integration – Ensure compatibility with crimping machines, feeding systems, and Industry 4.0 networks.

After-Sales Service – Reliable suppliers provide local support and spare parts to maintain uptime.

ROI (Return on Investment) – Automation usually pays for itself quickly in reduced labor costs and scrap rates.

ROI Analysis: Manual vs. Automated Solutions

| Tool Type | Cost | Output (per hour) | ROI Impact |

|---|---|---|---|

| Manual Tools | $20–$50 | ~200 cables/hr | Low |

| Semi-Automatic Equipment | $500–$2,000 | 600–1,000 cables/hr | Moderate |

| Fully Automatic Stripper | $1,500+ | 2,000–5,000/hr | High, payback in months |

Example:

A factory processing 10,000 cables daily can save up to $80,000 annually by upgrading to automation.

Conclusion

With the rapid rise of renewable energy, EV charging, and industrial automation, investing in professional large-gauge stripping solutions is no longer optional—it’s a strategic necessity.

Reduce waste

Improve safety

Boost profitability

The right wire stripper not only saves time but also secures long-term production quality. As technology evolves, we will see even more precise, efficient, and user-friendly solutions for handling heavy-duty cables.

Explore More: