How Automatic Terminal Crimping Machines Improve Wire Cutting & Stripping Efficiency

In today’s wire harness industry, boosting efficiency isn’t just about speed—it’s about smarter processes. Many factories still rely on manual cutting, stripping, and crimping methods, which limit output and increase labor costs.

More manufacturers are now switching to automatic terminal crimping machines that integrate cutting and stripping into one streamlined workflow. This shift is helping reduce errors, improve production speeds, and simplify wire harness manufacturing.

➡️ Discover more in our Wire Cutting and Stripping Machines collection.

➡️ Discover more in our Wire Cutting and Stripping Machines collection.

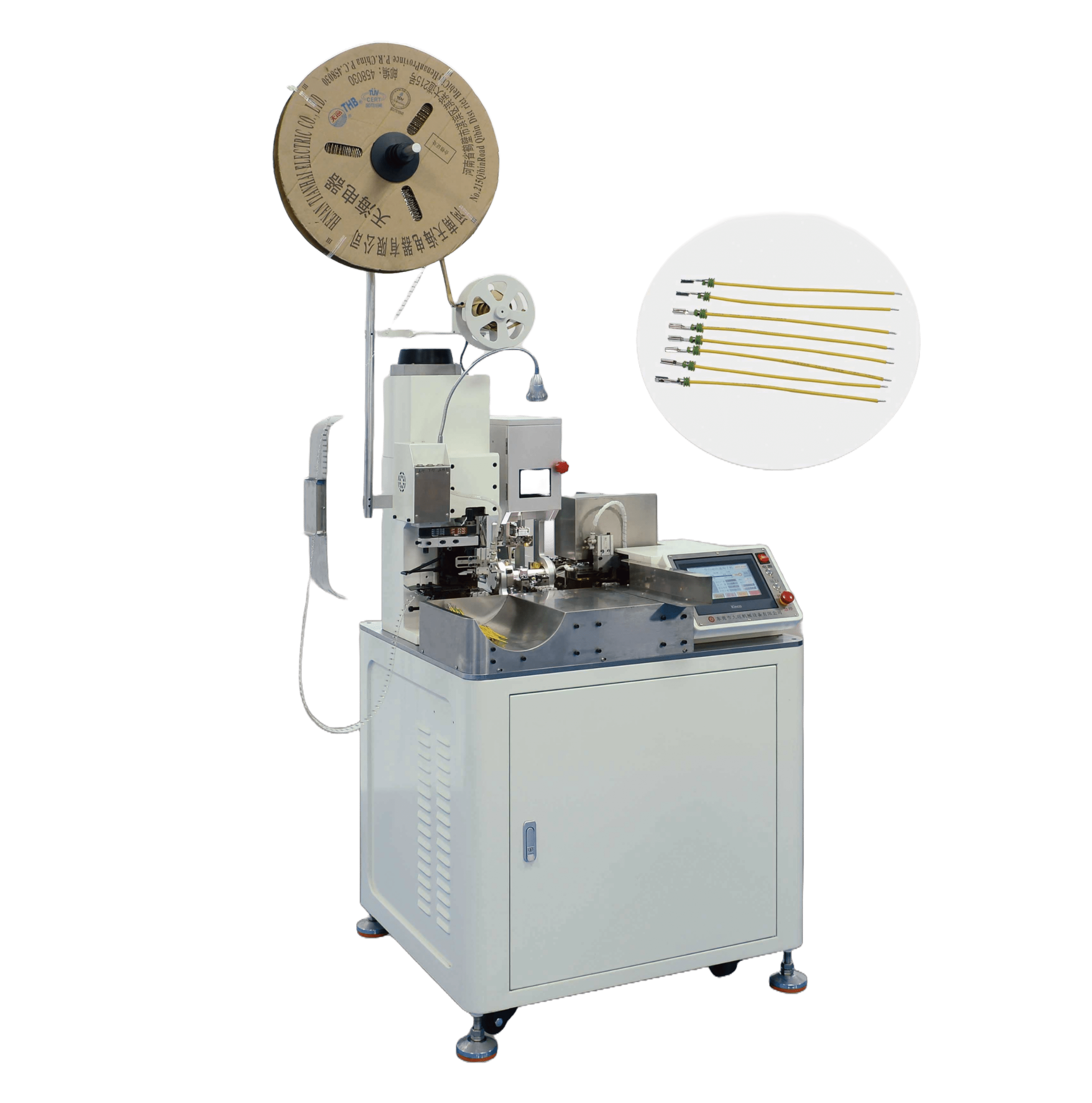

Cutting, Stripping & Crimping—All Combined in One Machine

With automated machines, you no longer need to transfer wires manually between different devices. These machines handle cutting, stripping, and terminal crimping in a single, seamless process.

➡️ See our full range of Terminal Crimping Machines.

Speed Comparison: See the Numbers

Our machines aren’t just fast on paper—they deliver real results in production lines.

| Machine Model | Processing Speed | Key Feature |

|---|---|---|

| KKD9 | 4,200 wires/hour | Triple-head crimping system |

| KK-507 | 800–2,000 wires/hour | Large cross-section stripping |

| Manual Setup | 200–500 wires/hour | Labor-intensive |

➡️ Browse high-speed crimping systems: Terminal Crimping Machines.

➡️ Browse high-speed crimping systems: Terminal Crimping Machines.

Precision Engineering for Consistent Results

Speed means nothing without accuracy. Our machines deliver ±0.1 mm precision per cycle and feature crimp force monitoring to prevent defects before they happen.

➡️ See our precise solutions: Terminal Crimping Machines.

➡️ See our precise solutions: Terminal Crimping Machines.

Is It Worth the Investment?

While upfront costs for automated systems may seem high, many factories recover their investment in months through labor savings and faster output. Our machines also require minimal maintenance for long-term reliability.

➡️ Explore more automation tools: Wire Twisting Machines.FAQs: Quick Answers

- Q: Are these machines compatible with waterproof connectors?

A: Yes, we offer waterproof insertion models for IP-rated connectors. - Q: How precise is the crimping process?

A: Every cycle delivers ±0.1 mm accuracy with defect monitoring. - Q: Can these machines handle large production runs?

A: Absolutely—they’re built for high-output production lines.

Recommended Learning Resources

Ready to Upgrade Your Wire Processing Line?

See all our Wire Processing Machines and request a personalized quote today.

Request a Quote