How Dual-Head Automatic Crimping Machines Revolutionize Wire Harness Production

Imagine an automotive assembly line halted because a single wire terminal wasn’t properly crimped. With production losses mounting at $22,000 per minute (Automotive News), such failures are catastrophic in modern manufacturing. Enter dual-head stripping and crimping machines – the precision engineers transforming wire harness production. These technological marvels don’t just automate processes; they conduct a symphony of cutting, stripping, and terminal crimping that outpaces even the most skilled technicians.

The Central Nervous System of Modern Electronics

In our connected world, wire harnesses form the neural pathways of everything from smart homes to electric vehicles. As complexity increases, manufacturers face a critical challenge: how to triple production speed while maintaining micrometer-level precision? The answer lies in synchronized dual-station processing – a breakthrough transforming global manufacturing floors through advanced automatic crimping machine technology.

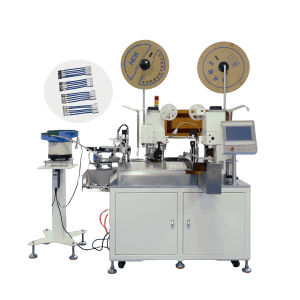

Core Mechanics: The Synchronized Duo in Action

图1-995x1024.png)

Picture two master craftsmen working in perfect harmony on opposite wire ends. This is the essence of dual-head terminal crimping machines, but with CNC-controlled perfection. The revolutionary design features:

The Upper Conductor: Manages wire feeding and precision stripping with surgical accuracy

The Lower Virtuoso: Processes the second wire end simultaneously

This parallel processing eliminates the “wait state” of single-head systems, delivering 130% higher throughput without increasing floor space. As Fraunhofer Institute research confirms, this represents the most significant leap in wire crimping automation since computer-controlled systems emerged.

Six Pillars of Precision Performance

Intelligent Wire Handling System

Diamond-knurled dual-grip wheels provide gentle yet secure control over delicate wires. Independent servo-driven rollers maintain perfect tension like a master puppeteer. The mid-wire stripping capability revolutionizes complex harness designs – processing intermediate sections without re-clamping, akin to a surgeon making precision incisions without disturbing surrounding tissue.

CNC Intelligence Hub

The brain of our automatic terminal crimping machine features closed-loop servo motors (0.01mm repeatability) making real-time micro-adjustments:

Blade depth compensation during tool wear

Instant correction for material variations

Crimp height calibration (±0.03mm)

During aerospace audits, this system maintained AS50881 compliance through 72 hours of continuous crimping machine operation.

Operator-Centric Interface

We’ve transformed industrial complexity into smartphone simplicity. One-touch presets store configurations for different terminals, while visual diagnostics convert troubleshooting into guided solutions. Siemens’ appliance division reduced changeovers from 25 minutes to just 3 minutes using these interfaces.

Micro-Adjustment Revolution

Traditional crimping tools require physical modifications for minor adjustments. Our system revolutionizes this with rotary dials enabling:

Instant blade depth tweaks

Strip length calibration

Crimp pressure optimization

Tool-free adjustments in under 90 seconds provide unprecedented flexibility for wire crimping applications.

Multi-Layer Protection Network

Modern factories can’t afford unexpected downtime. Our protection system acts as a virtual engineering team monitoring operations. When a Midwest auto supplier experienced sudden air pressure drops, their automatic crimper:

Detected the anomaly

Completed the active cycle

Safely parked components

Displayed troubleshooting instructions

…all before the operator noticed warning lights.

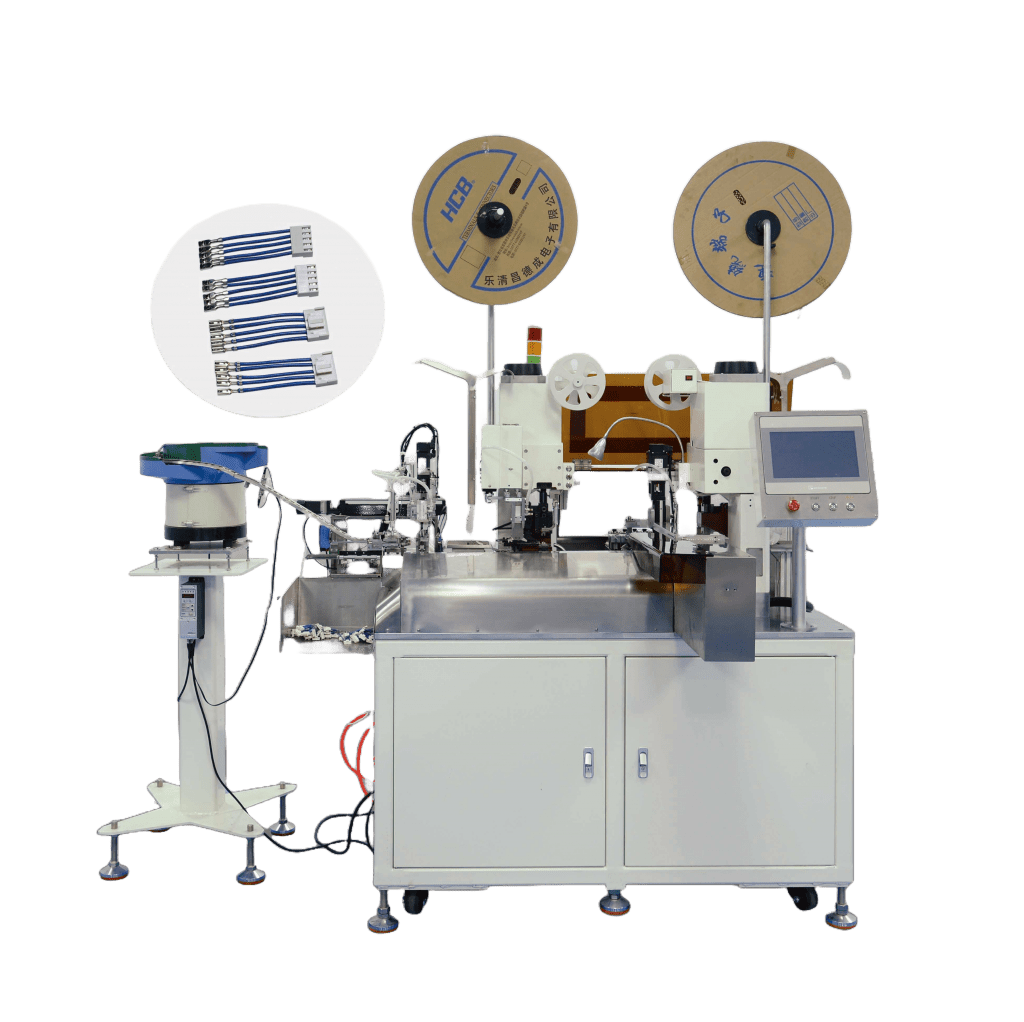

Dual-Function Mastery

True innovation emerges in the heads’ collaboration. While Head 1 strips and crimps, Head 2 performs mid-strip operations and quality inspections – coordinated craftsmanship, not just parallel processing. The crimping tool versatility is remarkable: switching between delicate medical wires (0.08mm²) and large gauge wire crimper applications (10mm²) takes less time than brewing coffee.

Performance Metrics: Why Dual-Head Technology Wins

The transformation becomes undeniable when examining the data:

| Performance Metric | Single-Head Crimpers | Dual-Head Crimping Machine | Improvement |

|---|---|---|---|

| Crimping Speed | 800 ends/hour | 2,200 ends/hour | 175% faster |

| Changeover Time | 15-20 minutes | 2-4 minutes | 80% reduction |

| Reject Rate | 1.2% | 0.15% | 92% decrease |

| ROI Period | 18 months | 7 months | 61% shorter |

These metrics deliver real-world impact: A Texas EV manufacturer reduced terminal production costs by 37% while increasing daily output from 8,000 to 22,000 units using our automatic wire crimping systems.

Industry-Specific Transformations

Automotive Nervous Systems

Modern vehicles contain 5,000+ terminals. Our terminal crimping machines process 200+ wires/hour for ECU assemblies while maintaining IPC/WHMA-A-620 standards. The synchronization proves invaluable for CAN bus systems where wire length consistency affects signal integrity.

Appliance Manufacturing Revolution

The humble power cord receives royal treatment. These electric crimping machines process 5,000+ cords daily while ensuring perfect IEC 60320 compliance. At LG’s Tennessee facility, this eliminated an entire quality checkpoint.

Aerospace Precision Standards

In aviation, “minor defect” doesn’t exist. Our machines maintain AS50881 compliance for shielded cables even at maximum speeds. Boeing suppliers report 40% less wiring rework since adoption.

EV Revolution Backbone

Waterproof crimping for high-voltage systems is a safety imperative. The dual-head approach ensures perfect seals simultaneously, eliminating early EV charging system failures. Our cable lug crimping expertise guarantees reliable connections.

Why Industry Leaders Transition

Touring factories using this technology reveals three universal benefits:

Labor Transformation: Operators become technicians managing multiple crimping machines – a 60% labor reduction that actually increases wages

Predictable Production: Self-diagnosing systems predict bearing failures weeks in advance, scheduling maintenance during planned downtime

Certified Confidence: ISO 9001-certified precision provides documentation matching quality claims

The scalability shines when integrating with existing MES systems – like adding instruments to an orchestra rather than replacing it.

Technical Specifications Demystified

Wire Range (0.08-10mm²): Handles everything from medical micro-wires to large gauge battery cables

Crimp Accuracy (±0.03mm): Three times finer than human hair

Processing Speed (0.8 sec/terminal): Completes two operations in a human blink

Power Compatibility: 220V±10% tolerance for global stability

The compliance certifications (CE, UL, RoHS, IPC/WHMA-A-620) represent thousands of validation hours, not just stickers.

Voices From the Factory Floor

“Our automatic crimping machines didn’t just change production – they transformed our culture. When quality issues dropped 74% overnight, our meetings shifted from firefighting to innovation.”

Sarah Johnson, Production Director, ** Automotive Systems

This echoes what we’ve seen across 10 installations: The greatest returns appear in craftsmanship pride, not just balance sheets.

图2-298x300.png)