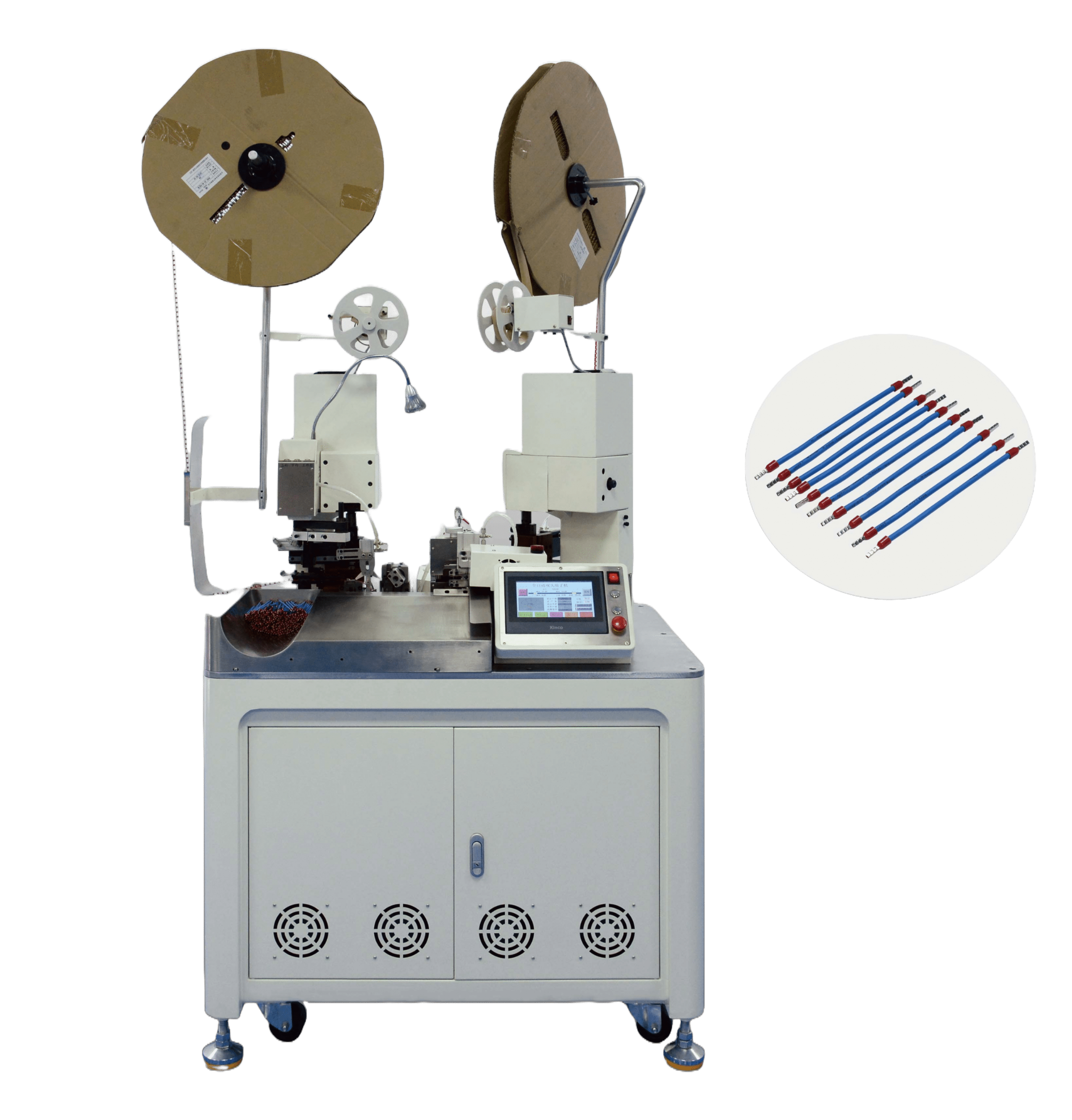

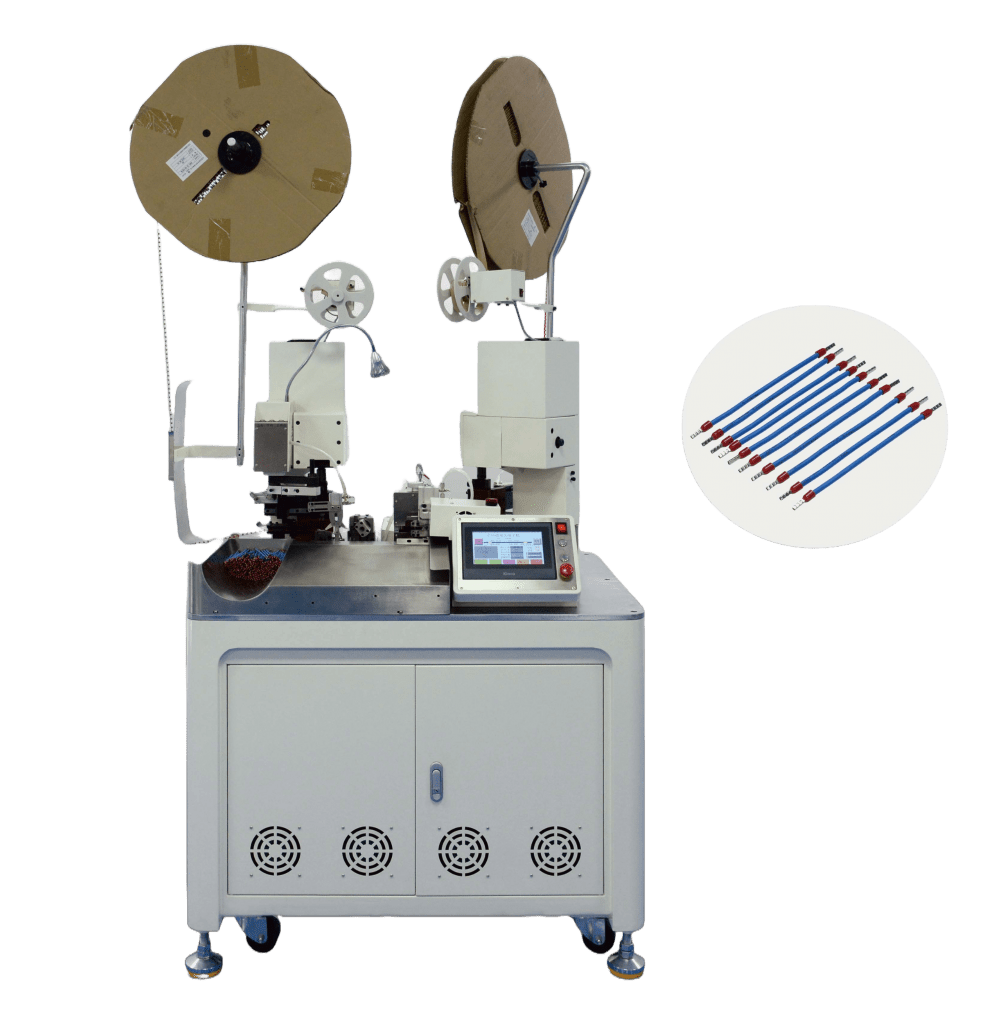

Real-World Efficiency: Why the KKD3 Automatic Terminal Crimping Machine Stands Out

Looking for a terminal crimping machine that actually performs on the production floor? Discover how the KKD3 improves efficiency, cuts errors, and streamlines your wire processing workflow—backed by real use cases and operator insight.

A Machine Designed for Real Manufacturing Needs

We get it—when you’re processing thousands of wires per shift, every second counts. That’s exactly why the KKD3 was built. It’s more than a spec sheet machine; it’s a tool trusted by real operators in automotive, appliance, and industrial wiring setups.

One customer in Southeast Asia shared this: “Since switching to the KKD3, our output per operator nearly doubled, and we’ve reduced manual rework by 60%.”

See our machine in action on YouTube

What Makes the KKD3 Crimping Machine So Practical?

-

True One-Touch Automation: Wire goes in, finished product comes out. It handles cutting, stripping, twisting, and both ends’ crimping without needing constant adjustments.

-

Proven Output: Runs up to 1,400 wires/hour for standard 300mm lengths. That’s serious throughput for busy shops.

-

Flexible Wire Support: Handles AWG14 to AWG28, so you’re covered from thick cables to fine signal wires.

-

Accurate Every Time: With a cutting tolerance of ≤1mm + 0.2%, your terminations meet strict OEM specs.

-

Operator-Friendly Interface: One of our clients said, “I trained a new staff member in under an hour thanks to the clear touchscreen menus”.

Quick Specs at a Glance

| Feature | Detail |

|---|---|

| Model | KKD3 |

| Voltage | AC220V, single-phase, 50/60Hz |

| Processes | Wire cutting, double-end twisting, crimping |

| Speed | Up to 1,400 pcs/hour (for ≤300mm wires) |

| Supported Wires | AWG14–28 (1.6–0.08mm²) |

| Cutting Lengths | 50mm–9,999mm |

| Accuracy | ≤1mm + 0.2% |

| Stripping Length | 7–12mm |

| Crimping Force | 2.0T (option: 3.0T) |

| Air Requirements | 4–6 kgf, clean & dry |

| Detection | Optical sensors, crimp verification, wire jam alert |

| Size | 700W × 800L × 1500H (mm) |

| Weight | ~358kg |

Built for Demanding Applications

Whether you’re producing automotive wire harnesses, appliance leads, or industrial cable assemblies, the KKD3 fits seamlessly into your workflow.

Built for Demanding Applications

Whether you’re producing automotive wire harnesses, appliance leads, or industrial cable assemblies, the KKD3 fits seamlessly into your workflow.

Real-World Applications:

-

Automotive control wire systems

-

Home appliance harness assembly

-

Industrial automation cables

Common Questions We Get

Q: Is it hard to set up for a new wire batch?

A: Not at all. Just input your specs into the touchscreen. Many users get up and running with new wire sizes in 3–5 minutes.

Q: What if something goes wrong mid-run?

A: Sensors detect jams, air issues, or missing crimps and stop the machine instantly. You’ll see the error right on the screen.

Q: Can I use third-party terminals?

A: Yes, as long as they’re continuous sheathed type. Many of our customers use multiple brands without issue.

Customers tell us the KKD3 isn’t just “another crimping machine.” It’s a labor-saver, a mistake reducer, and—most importantly—a machine that actually helps them hit deadlines.

If you’re serious about scaling your production, minimizing downtime, and getting clean, strong crimps every time, the KKD3 deserves a place on your floor.

Ready to Take Your Wire Processing to the Next Level?Talk to our engineers today about how cablemachineries can give solutions to fit into your workflow.