Engineered for wire harness manufacturers who prioritize speed, consistency, and space-saving automation.

🔧 Stop Wasting Time on Disconnected Processes

Still handling wire cutting, stripping, terminal crimping, and tin dipping across multiple stations or machines?

That old method leads to:

-

Inconsistent crimps due to human error

-

Oxidation from delays between processes

-

Slowdowns in takt time and floor efficiency

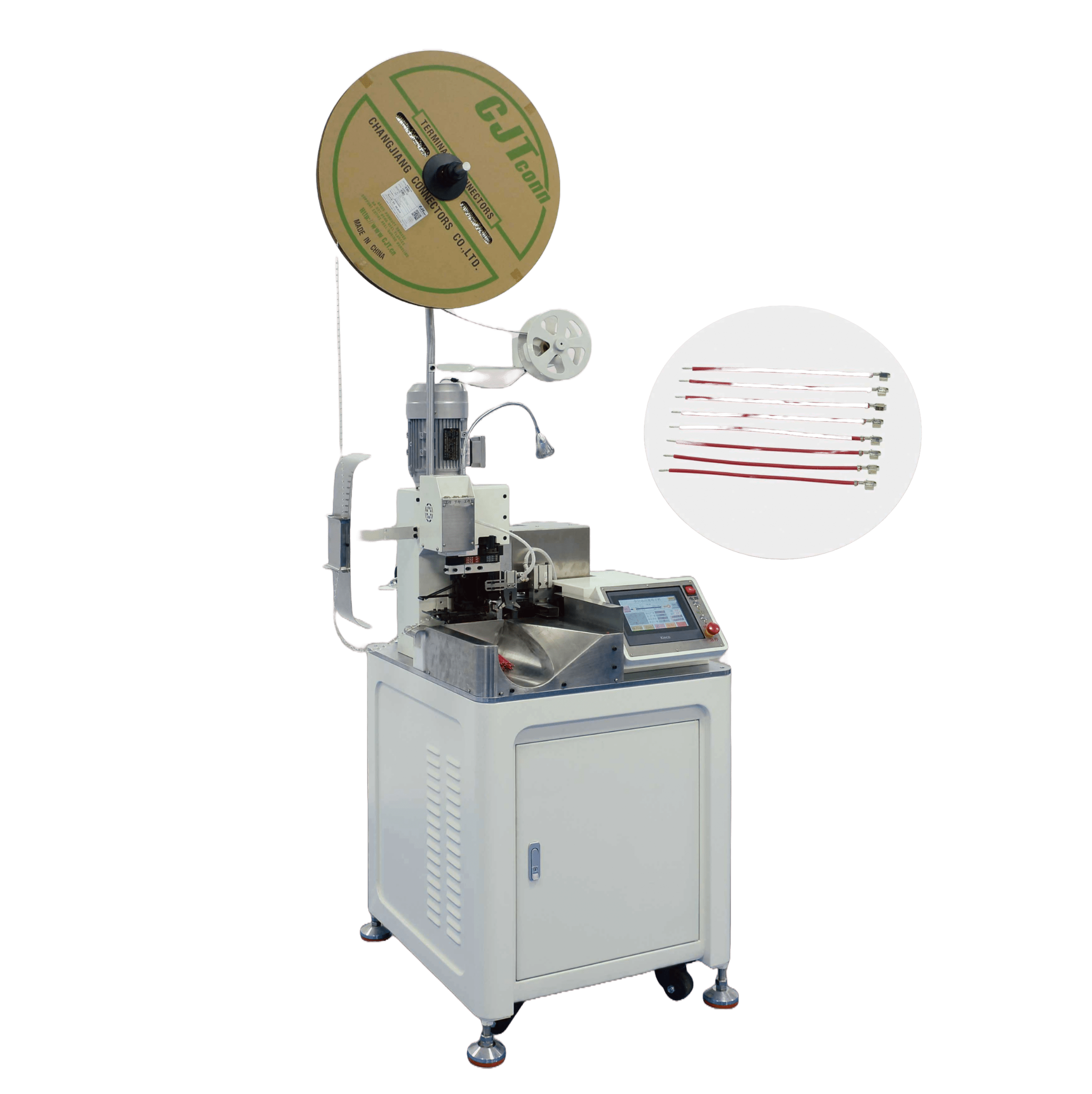

This all-in-one wire cutting crimping machine changes that. We engineered it from the ground up to solve those pain points by bringing everything—cut, strip, crimp, tin—into one precise and continuous process.

⚙️ Integrated Design. Consistent Output. Real Throughput.

No more switching between workstations or babysitting multiple setups. This machine’s linear architecture synchronizes wire feeding, stripping, dual-end terminal crimping, and post-crimp tin dipping with millimeter-level accuracy.

It’s ideal for:

-

Automotive harnesses

-

Industrial relay/power assemblies

-

Consumer electronics cabling

-

EV battery leads or PCB interconnects

✅ Core Capabilities at a Glance

| Feature | Detail |

|---|---|

| Wire Types | 16–32 AWG round wires, 2P–20P ribbon cables |

| Processing Flow | Cut → Strip → Crimp (both ends) → Tin Dip |

| Wire Length | 35–1000 mm |

| Strip Length | 1–13 mm |

| Speed | Up to 5,000 wires/hour |

| Output | 5-wire simultaneous feed |

⚠️ Pro tip: If your daily volume is over 2,000 wires, you’re losing time and money without this level of automation.

🔩 Built for Demanding Production Environments

Every mechanical element is designed for continuous duty cycles:

-

Leadshine/Lexium servo motors (6x) for multi-axis precision

-

HIWIN linear guides + ball screws (Taiwan) ensure long life

-

Omron sensors monitor each process in real time

-

Star pneumatic cylinders + Korea YSC solenoids for fast, reliable actuation

-

7” Kinco touchscreen (EN/CN interface) for intuitive control

Control everything from a single interface. Adjust wire length, tin depth, crimp pressure, or save programs—no engineering degree needed.

🧪 Where This Machine Shines

Your wire harness assembly process needs reliability without the footprint. This machine is especially valuable for:

-

Factories with limited floor space

-

Assembly lines where crimping errors or cold solder joints cause rework

-

Teams aiming for ESG-compliant, energy-efficient manufacturing

🗂️ Case in Point:

A customer in Vietnam replaced three separate machines with this one platform. They doubled throughput while eliminating 2 operator positions—without sacrificing quality.

Work Smarter with Less Space

Thanks to its compact footprint (1900 × 760 × 1500 mm) and five-wire feed design, this machine fits inside tight production lines and still performs like a multi-station setup.

No more belt alignments or downtime. Servo drive replaces traditional mechanical systems and blade change takes minutes—not hours.

Whether you’re a lean startup or a growing OEM harness shop, this machine helps you scale cleanly and reliably.

🧾 Full Technical Specifications

| Parameter | Value |

|---|---|

| Dimensions | 1900 × 760 × 1500 mm |

| Weight | 350 kg |

| Wire Gauge | 16–32 AWG |

| Ribbon Cable | 2P–20P supported |

| Strip Length | 1–13 mm |

| Cutting Length | 35–1000 mm |

| Max Output | 5,000 pcs/hour |

| Control System | Single-chip |

| Servo Axes | 6 (Leadshine/Lexium) |

| Sensors | Omron (Japan) |

| Guide Rail | HIWIN (Taiwan) |

| Pneumatics | Star + YSC |

| Display | 7″ Kinco touchscreen |

| Power | AC 220V, 180–600W |

❓ FAQs — You Asked, We Answered

Q: What types of terminals can it crimp?

A: It supports standard OTP bayonet applicators. For European or custom applicators, we can adjust the crimp stroke to 40 mm.

Q: Does it support flat cables?

A: Yes. With custom guides, it processes flat ribbon cables up to 20P.

Q: Is it hard to train operators?

A: Not at all. Most teams are up and running within 2 hours. Our team provides video support, English manuals, and real-time remote guidance.

🔗 Explore More

📄 Learn more about our company on the About Us page

🛠️ Browse more terminal crimping machines at cablemachineries.com

📩 Contact us now for a fast quote or machine demo

🚀 Why Upgrade Now?

Unlike generic crimpers or semi-automated setups, this system offers true inline processing with minimal touchpoints. It’s built for scale and pays for itself in speed, uptime, and reliability.

If your business is moving from manual to smart automation, this is the wire cutting crimping machine that lets you take the leap—without losing quality or control.