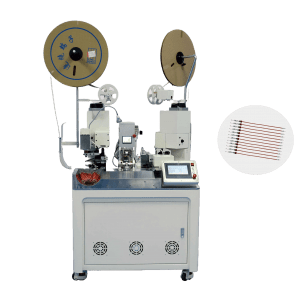

KKT Automatic Wire Twisting and Crimping Machine

The KKT Automatic Wire Twisting and Crimping Machine offers integrated wire cutting, stripping, conductor twisting, and terminal crimping for high-volume wire harness production. Designed for AWG12–AWG28 wires, this machine boosts efficiency and ensures consistent, high-precision results.

What the Automatic Wire Twisting and Crimping Machine Does

The KKT (Twisting Model) is an all-in-one wire processing machine designed for efficient terminal assembly. It handles double wire cutting, single-end stripping & twisting, and single-end crimping in a single automated workflow. Ideal for AWG12–AWG28 wires (0.8–4.4mm diameter), it cuts wires from 45mm to 9,999mm (with custom lengths available) and strips 1.0–15mm of insulation from one end before twisting conductors and crimping terminals. Capable of processing 4,000 pieces per hour for wires ≤100mm, it streamlines production for harnesses, cables, and connectors requiring twisted and crimped ends.

Functions & Specifications

| Function | Details |

|---|---|

| Model | KKT (Twisting Model) |

| Power Supply | AC220V, 50/60Hz, Single-phase |

| Functions | Double wire cutting, single-end stripping & twisting, single-end crimping |

| Production Capacity | 4,000 pcs/h (wire length ≤100mm) |

| Wire Range | AWG12–AWG28 (0.8–4.4mm diameter) |

| Cutting Length | 45mm–9,999mm (custom lengths available) |

| Cutting Precision | ≤1mm + 0.2% of cutting length |

| Stripping Length | 1.0–15mm |

| Crimping Power | 0.75KW |

| Air Pressure | 4–6 kgf (clean, dry air required) |

| Detection Systems | Wire presence, terminal crimp check, wire jam, low air pressure detection |

| Dimensions | 650W × 700L × 1500H (mm) |

| Weight | ~308KG |

Applications

This automatic wire twisting and crimping machine is widely used in the production of automotive harnesses, electrical control boxes, power connectors, and industrial automation wiring systems. It is especially suitable for operations requiring stable twisted conductors and accurate terminal crimping in large quantities.

Frequently Asked Questions

- Can it process different wire diameters?

Yes, it supports AWG12 to AWG28 wires. - What’s the required air pressure?

4–6 kgf using clean and dry compressed air. - Is customization available for wire length?

Yes, we support custom cutting lengths up to 9999mm.

Additional Resources

Learn more about wire stripping and crimping technology on Wikipedia.

图1-600x601.png)

Reviews

There are no reviews yet.