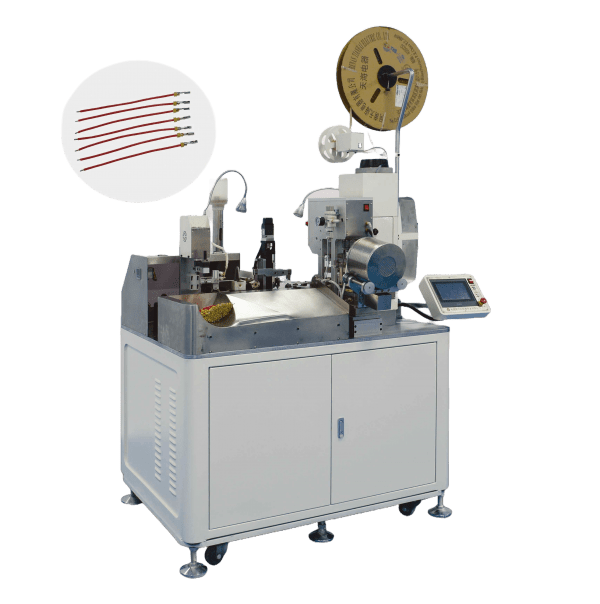

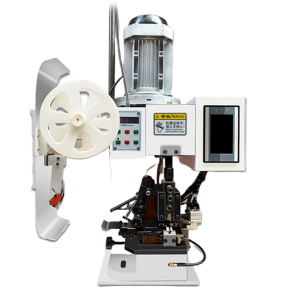

Double-Head Terminal Crimping and Tinning Machine – All-in-One Automation

This double-head terminal crimping and tinning machine is an advanced solution for high-speed wire processing, offering wire cutting, single-end stripping, terminal crimping, twisting, and tin dipping—all in a fully automated cycle. Built to handle AWG#28–#16 wires, this machine delivers ≤0.1mm precision and boosts throughput up to 1,200 pcs/hour. It’s perfect for automotive waterproof connectors, marine electronics, and industrial wire harness assembly.

🔧 Double-Head Terminal Crimping and Tinning Specifications

| Specifications | Details |

|---|---|

| Functions | Cutting, stripping, waterproof grommet insertion, double-end crimping, twisting, tinning. Configurable: front (strip/grommet/crimp), rear (strip/twist/tin). |

| Wire Range | AWG#28–#16 (0.08–1.5mm²) |

| Production Capacity | Up to 1,200 pcs/hour (based on wire spec) |

| Cutting Precision | ≤0.1mm (≤100mm); ≤0.2mm (>100mm) |

| Stripping Length | Front: 0.1–12mm; Rear (tinning): 0.1–15mm |

| Min. Sheath Retention | 40mm (shorter possible with modifications) |

| Detection Systems | Wire presence, low air pressure, crimping errors, feeding faults |

| Power Supply | AC200–250V, single-phase, 50/60Hz, 10A |

| Air Pressure | 0.5 MPa (5kgf/cm²), dry air |

| Dimensions | W1,220 × D1,000 × H1,520 mm |

| Weight | Approx. 450 kg |

📦 Applications for Double-Head Crimping & Tinning

In high-volume cable assembly, this double-head terminal crimping and tinning machine automates complex end processing, improving uniformity and saving labor. Widely used in automotive wire harnesses, marine connectors, and appliance manufacturing.

💬 FAQs on Crimping and Tinning Equipment

Can this machine handle both waterproof and standard terminals?

Yes. With tooling changes, it can switch between grommeted and non-grommet terminals.

Is the tinning temperature adjustable?

Yes, you can program both temperature and tin dip duration.

Is there global support available?

We provide remote installation guidance, manuals, and international shipping for spare parts and training.

🔗 Learn More About Crimping & Tinning

Explore crimping technology and IPC standards for wire harnesses. Also see ISO 6722 wire specifications.

Reviews

There are no reviews yet.