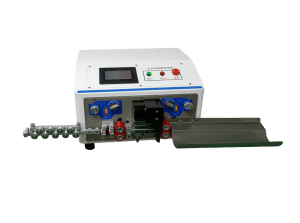

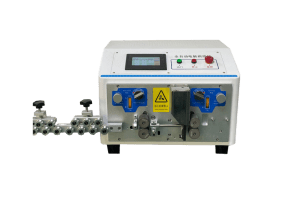

What It Does

The KKT3 is a fully automatic terminal machine designed for triple-end crimping, handling wire cutting, single/double-end stripping, and three-terminal crimping in one workflow. It processes AWG#30–#16 wires, cutting them from 41mm to 99,999mm (shorter lengths customizable) with precision up to ≤0.2 + (L×0.002)mm for wires ≤100mm. The machine strips 0.5–8.0mm at the front end and 0.1–10.0mm at the rear, then crimps three terminals simultaneously—ideal for complex harnesses needing multi-point connections. With a capacity of 3,000 pcs/h for 50–100mm wires, it’s built for high-volume automotive, electronics, and industrial wiring.

图1-600x612.png)

Reviews

There are no reviews yet.