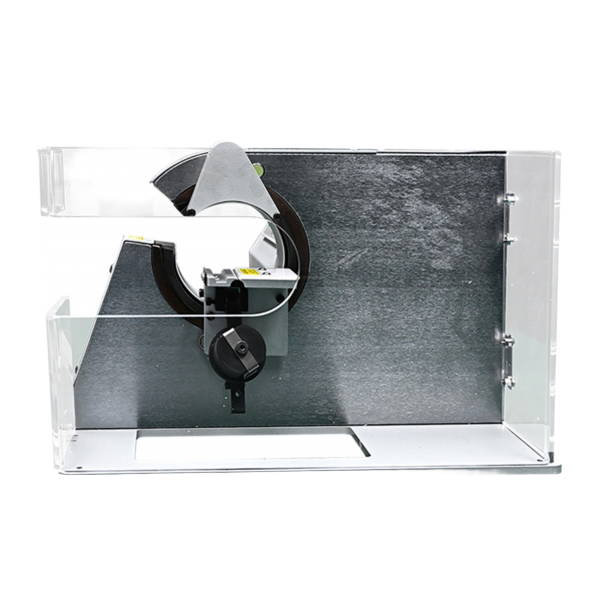

KK-T03 Intelligent Tape Wrapping Machine | Automotive Wire Harness Solution

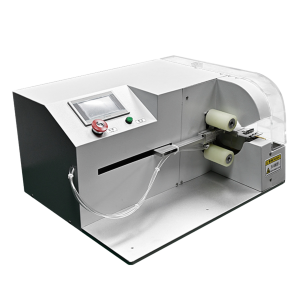

The KK-T03 Intelligent Tape Wrapping Machine is a compact, high-precision solution for spiral wrapping of automotive wire harnesses. With multiple wrapping modes (spot, segmented, continuous) and bidirectional rotation (300-2500 RPM), it delivers wrinkle-free finishes on 3-25mm wires using various tapes including high-temperature, mica, and ceramic fiber tapes.

🔧 KK-T03 Tape Wrapping Machine Specifications

| Model | KK-T03 |

| Dimensions | 430 × 380 × 260 mm (ultra-compact) |

| Wire Diameter Range | 3–25 mm |

| Power Supply | 220V / 110V (specify when ordering) |

| Spindle Speed | 300–2500 RPM (variable) |

| Rotation Direction | Forward & Reverse |

| Wrapping Method | Spiral Wrapping |

| Compatible Tapes | High-temp, Mica, Ceramic fiber, PVC, Vinyl, Cloth-based, Fleece |

| Tape Loading | Fixed ring design for quick replacement |

| Cooling System | Built-in ventilation and cooling fan |

| Cutting Mechanism | Precision blade with clean cutting |

| Wrapping Quality | Smooth, wrinkle-free with stable tension |

| Wrapping Modes | Spot, Multi-section, Continuous |

🚗 Key Applications

Automotive Cable Assemblies

Precision wrapping of engine bay harnesses, dashboard wiring, and EV battery connections with heat-resistant tapes.

Industrial Machine Harnesses

Bundling and protection of control cabinet wiring for CNC machines, robotics, and heavy equipment.

High-Temperature Insulation

Critical applications requiring ceramic or mica tape wrapping in high-heat environments.

💡 Key Features & Advantages

Bidirectional WrappingForward/reverse rotation for complex harness geometries

Multiple Taping ModesSpot, sectioned & continuous wrapping for varied requirements

Multi-Tape CompatibilityHandles heat-resistant to soft fleece tapes seamlessly

Active Cooling SystemPrevents overheating during extended production runs

Quick Tape ReplacementFixed ring design changes tapes in under 30 seconds

Premium Wrapping QualityLaser-guided tension control ensures wrinkle-free results

🏭 Production Floor Advantage

“The KK-T03’s compact size (43% smaller than previous models) allowed us to integrate 6 units into our existing Toyota harness line without layout changes. Its multi-section wrapping mode reduced material waste by 28% during complex junction wrapping.”

— Production Manager, Tier 1 Automotive Supplier

📊 Technical Comparison

| Feature | KK-T03 | Standard Machines |

|---|---|---|

| Footprint | 0.11 m² (430×260mm) | 0.35-0.5 m² |

| Wrapping Modes | 3 (Spot/Segment/Continuous) | 1-2 Modes |

| Tape Change Time | ≤30 seconds | 2-3 minutes |

| Max Wire Diameter | 25mm | 15-20mm |

| Rotation Control | Bidirectional | Unidirectional |

💬 Frequently Asked Questions

What’s the minimum wrap length in spot mode?

The KK-T03 can perform spot wraps as short as 15mm with precision positioning accuracy of ±0.5mm.

Can it wrap overlapping sections?

Yes, the multi-section mode allows programming up to 20 separate wrap zones on a single harness with different overlap percentages.

How does the cooling system work?

Dual ball-bearing fans provide active airflow across motor components, maintaining optimal temperature during 24/7 operation.

Is training included?

Yes, we provide comprehensive onsite training plus video manuals covering all wrapping modes and maintenance procedures.

Ready to Enhance Your Harness Production?

Includes full specifications, application guide, and integration options

Reviews

There are no reviews yet.