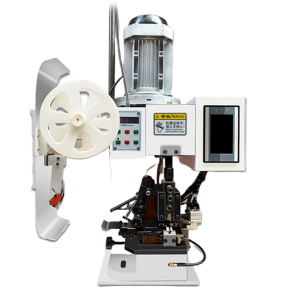

1.5T Terminal Crimping Machine – Model KK-1.5T

The KK-1.5T Terminal Crimping Machine is designed for high-efficiency terminal pressing in wire harness assembly. With precise adjustable stroke options, wide mold compatibility, and compact size, it is ideal for electronics, automotive, and industrial cable production.

🔧 Terminal Crimping Machine Specifications

| Model | KK-1.5T |

| Crimping Force | 1.5 Tons |

| Stroke Length | 30mm (Default) / 40mm (Customizable) |

| Voltage | AC 220V 50/60Hz (110V Available) |

| Main Motor Power | 0.55 kW |

| Control Board Power | 0.75 kW |

| Crimping Speed | 40–80 times/min (Adjustable) |

| Crimping Range | Up to 2.5 mm² |

| Applicable Dies | Horizontal, vertical, single-pin, or hexagonal dies |

| Machine Dimensions | 215 × 250 × 600 mm |

| Weight | 33 kg |

✅ Key Features of KK-1.5T Terminal Crimping Machine

- ⚙️ Precision crimping for small and medium terminals

- 🔁 Adjustable stroke (30mm or 40mm)

- 🧩 Compatible with multiple die types without modification

- 📈 Stable crimping force with low vibration

- ⚡ High-speed operation up to 80 crimps per minute

- 🔌 Dual-voltage support for global use (110V/220V)

- 🧰 Optional pressure monitoring module available

🔍 Applications of the Terminal Crimping Machine

- 🚘 Automotive wiring harness assembly

- 📺 Consumer electronics cable processing

- 🏭 Industrial connector crimping

- 📡 Signal wire terminal pressing

- 🔌 Power cable and plug assembly

🏭 Use Case Example

In a wire harness factory, the KK-1.5T is used for mass production of automotive connectors. By switching between horizontal and hexagonal dies, operators achieve flexible terminal processing with a consistent crimping force. The addition of a pressure sensor ensures quality control and rejects faulty crimps in real time.

💬 Frequently Asked Questions

Can it support both 110V and 220V?

Yes. Please specify voltage requirement when ordering.

Can it be customized with a pressure monitoring system?

Yes. Optional pressure detection module can be added to monitor crimping consistency.

What kind of dies can be used?

It supports horizontal dies, vertical dies, single-pin molds, and hexagonal molds with tool-free switching.

What is the recommended maintenance?

Regular lubrication and die inspection every 2 weeks are recommended. Replace worn parts as needed.

Learn more about crimping technology or ISO 11494 crimping standards.

📩 Request Free Product Demo

Contact our engineers for technical specifications sheet

Reviews

There are no reviews yet.