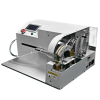

Tape Wrapping Machine with Clamp – Model KK-T02 | Automotive Wire Harness Solution

The Intelligent Tape Wrapping Machine KK-T02 with Clamp is engineered for precision wrapping of automotive wire harnesses. Featuring a specialized clamping mechanism and 4500 RPM spindle speed, it ensures consistent, tight, and durable tape coverage for wire diameters 3-25mm. Ideal for high-volume production of vehicle cable assemblies with various tape types including heat-resistant and abrasion-proof tapes.

🔧 Tape Wrapping Machine with Clamp Specifications

| Model | KK-T02 |

| Applicable Wire Diameter | 3–25 mm |

| Power Supply | 220V / 110V (specify when ordering) |

| Compatible Tape Types | High-temperature, Mica, Ceramic fiber, PVC, Vinyl, Fabric, Fleece tape |

| Machine Dimensions | 625 × 475 × 335 mm |

| Spindle Speed | 4500 RPM |

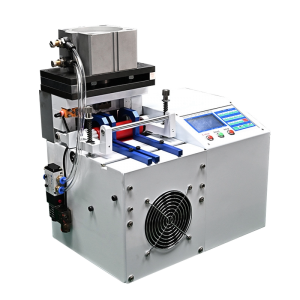

🚀 Key Features of KK-T02 Clamp-Type Tape Wrapper

- 🔒 Precision clamping mechanism for secure tape application

- 🔥 Supports heat-resistant tapes up to 200°C continuous use

- ⚡ High-speed operation at 4500 RPM spindle speed

- 🏭 Optimized for automotive wire harness production lines

- 📦 Compact footprint saves valuable production space

- 🔄 Automated tension control for consistent wrapping density

🔍 Applications of Clamp-Type Tape Wrapping Machine

- 🚗 Automotive wire harness tape bundling and protection

- 🔌 Cable insulation with high-temperature resistant tapes

- 🏭 Industrial machinery wiring systems

- 🏠 Home appliance internal wiring harnesses

- ⚡ High-voltage cable assemblies

🏭 Use Case: Automotive Wire Harness Production

In a Toyota supplier facility, the KK-T02 Tape Wrapping Machine processes 12,000 wire harnesses daily for hybrid vehicle power systems. The clamping mechanism ensures precise tape placement on high-voltage cables, while its compatibility with ceramic fiber tape provides critical heat protection near engine components, reducing warranty claims by 32%.

💬 Frequently Asked Questions

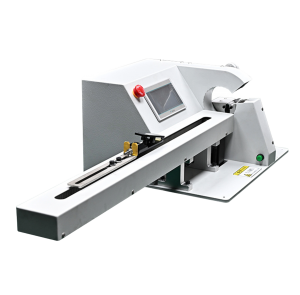

How does the clamp mechanism improve wrapping?

The precision clamp secures wires during wrapping, preventing rotation slippage and ensuring consistent tape overlap even at maximum 4500 RPM speed.

Can it handle irregularly shaped harnesses?

Yes, the adjustable clamp accommodates connectors, junctions, and non-circular harness sections up to 35mm diameter.

What’s the changeover time between tape types?

Average changeover takes under 5 minutes with our quick-release tape holders. Most settings are stored in programmable presets.

Is it compatible with robotic integration?

Yes, the KK-T02 features standardized M12 connectors for seamless integration with KUKA, Fanuc, and Yaskawa robotic arms.

Learn about SAE J1128 automotive cable standards or ISO 19642 wire harness specifications.

Reviews

There are no reviews yet.