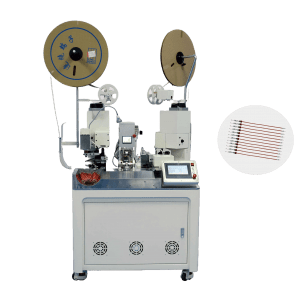

Terminal Crimping Machine (BVR wires)

The U/OT Type Terminal Crimping Machine is designed for precision terminal crimping of BVR wires ranging from 0.5mm² to 4mm².

It integrates electric, pneumatic, and smart motor control technologies, offering exceptional efficiency and safety features for semi-automatic wire harness assembly.

🔧 Key Features

- Supports BVR wires 0.5–4 mm² with adjustable stripping and crimping lengths

- Human-machine interface with memory function for quick changeover

- Terminal presence detection and safety door sensors

- Automatic trigger via wire feeding – no foot pedal required

- Compact footprint and energy-efficient 500W total power

📊 Technical Specifications

| Item | Specification / Description |

|---|---|

| Product | U/OT Type Terminal Crimping Machine |

| Control System | Human-machine interface, electric control, motor and pneumatic combined |

| Operation Mode | Wire feeding triggers automatic operation |

| Compatible Wire | Suitable for BVR wire 0.5–4 mm² |

| Stripping Length | Adjustable stripping range: 6 – 28 mm |

| Crimping Range | Maximum crimping length: 10 mm |

| Stripping & Insertion | Adjustable via motor parameters |

| Product Changeover | Manual tooling change; memory for stripping length and depth |

| Detection Features | Terminal presence and safety door detection |

| Power Supply | AC220V / 50Hz, 10A; Internal DC24V, DC36V; Total 500W |

| Air Supply | 0.5–0.7 MPa (clean, dry, stable air) |

| Working Temperature | 10–35°C |

| Working Humidity | 30–80% RH (non-condensing) |

| Dimensions | W700 × D605 × H1200 mm |

| Weight | Approx. 120 kg |

💼 Application Scenarios

This crimping machine is widely used in automotive wire harness workshops, household appliance assembly lines, new energy product lines, and automation testing labs requiring high-precision semi-automated terminal crimping for medium-size wires.

❓ Frequently Asked Questions

Q: Can I use this machine for non-BVR wires?

A: It is optimized for BVR wires, but with tooling adjustment, some other types may also be processed.

Q: Does the machine support automatic changeover?

A: No, tooling and feeder replacement are manual, but the system remembers past settings for fast restart.

Q: What air quality is required?

A: Ensure clean, dry, and stable compressed air between 0.5–0.7 MPa for optimal operation.

图1-300x306.png)

Reviews

There are no reviews yet.