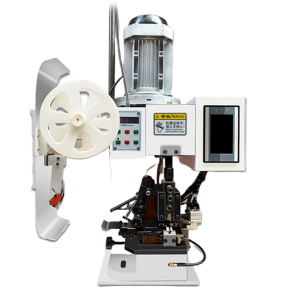

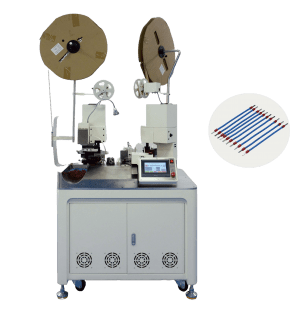

KK-Wire-Separating Stripping & Crimping Machine

Advanced Solution for Precision Wire Processing

The KK-Wire-Separating Stripping & Crimping Machine revolutionizes wire processing with specialized separation technology. Designed for industrial precision, it strips and crimps wires while maintaining perfect alignment—ensuring unmatched accuracy for automotive, appliance, and electronics manufacturing.

Key Features

- Advanced Wire Separation: Prevents tangling, keeps perfect wire alignment

- Precision Pneumatic Dies: Consistent high-quality crimps with accurate separation

- Adjustable Crimping Speed: 40–80 adjustable strokes/min

- Custom Voltage Option: 220V standard; 110V for global use

- Optional Pressure Monitoring: Real-time crimp consistency check

Core Specifications

| Item | Specification |

|---|---|

| Model | KK-Wire-separating |

| Motor Power | 0.75KW |

| Control Board Power | 1.5KW |

| Crimping Range | ≤4mm² |

| Crimping Force | 2 Tons |

| Crimping Speed | 40–80 adjustable strokes/min |

| Stroke | 30mm |

| Working Voltage | AC220V 50/60Hz (110V customizable) |

| Compatible Dies | High-precision pneumatic dies |

| Pressure Monitor | Optional Add-on |

| Dimensions | 270 × 300 × 710 mm |

| Weight | 45kg |

Advanced Features

🔗 Wire Separation Technology

Our proprietary wire separation system prevents tangling and maintains perfect alignment during processing. This innovative technology ensures each wire is precisely positioned for accurate stripping and crimping, even in complex multi-wire configurations.

🔧 Precision Tooling

Equipped with high-precision pneumatic dies that deliver consistent crimp quality. The tooling system is designed for quick changeovers and compatibility with a wide range of terminal types and wire gauges.

🧠 Intelligent Control System

The advanced control system allows operators to easily adjust crimping parameters, monitor production statistics, and diagnose issues. Optional pressure monitoring provides real-time quality control for each crimp.

Industrial Applications

- Automotive Harnesses

- Appliance Wiring

- Electronics Manufacturing

- Control Panels

- Telecommunications

- Aerospace Wiring

- Medical Equipment

- Robotics

Frequently Asked Questions

💡 What’s the benefit of wire-separating technology?

It prevents tangling, maintains perfect wire alignment, and improves processing accuracy for complex harnesses. This results in higher quality connections, reduced rework, and increased production efficiency.

🔄 Can it handle different wire gauges together?

Yes, the machine is specifically designed to maintain separation and alignment even with varying wire diameters. The adjustable tension settings allow operators to optimize the process for different wire combinations.

⚡ Is the production speed faster than traditional models?

Absolutely. The KK-WIRE-SEPARATING machine improves productivity by 50–70% compared to traditional models. It processes multiple wires simultaneously with precision alignment, reducing handling time and minimizing errors.

📉 How does the optional pressure monitoring work?

Sensors measure the crimp force in real-time, compare it to quality parameters, and alert operators if a crimp is out of range. This ensures consistent output and prevents defective products from continuing down the line.

Reviews

There are no reviews yet.