The stages of a wire harness’s life, from design to delivery

The Critical Design Stage: The Connectivity Blueprint

A reliable wire harness starts its journey long before any parts are put together. The wire harness design phase starts on a computer screen and sets the stage for everything else that comes after it. This step is probably the most important because a mistake here could cause problems with performance or make manufacturing more difficult later on.

So, what does it take to make a good designs? It takes a group effort, and the first step is to really understand what the application needs to do. Engineers need to figure out important electrical details, like what kinds of signals will be sent, what the voltage and current levels are, and how to reduce electromagnetic interference (EMI).

But that’s not all. The design needs to be strong enough for where it will be used. Will it have to work in very hot or very cold weather? Is it possible for it to be exposed to chemicals, moisture, or constant vibration and abrasion? To choose the right materials and safety measures, you need to be able to answer these questions.

This is when you need really good Computer-Aided Design (CAD) software. Engineers can use tools like Zuken and EMA-EDA to make detailed 2D diagrams and 3D models. These digital prototypes show exactly where every wire should go, where every connector should go, and the overall size of the harness. They also help you choose the right wire gauges, types of insulation, and protective sleeves like conduit or loom.

For a lot of businesses, it’s best to leave this kind of thing to the pros. This is where specialized wire harness design services come in handy. They give you access to engineers who can make the design better for performance, cost, and ease of production.

The Art of Assembly: How Wire Harnesses Are Made

The Non-Negotiable Testing Phase: Making Sure of Dependability

The Last Mile: Getting There and Getting Help

The last stage of the life cycle is all about getting the product to the customer quickly and safely. To keep things from getting damaged during shipping, it’s important to package and ship them carefully. A trusted manufacturer makes sure that the supply chain runs smoothly so that deliveries are always on time.

But for a top-tier wire harness supplier, the relationship goes beyond delivery. A trustworthy partner is one who offers ongoing support after the sale. This dedication to customer satisfaction builds long-term trust, whether it’s answering technical questions or fix problems after installation.

Final Thoughts

6. Why Choose Our Automatic Crimping Machine Factory?

Transparent pricing, fast quotation process

Free remote setup assistance + video training

Custom crimp settings for various terminal types

Strong export track record in EU, South America, and Southeast Asia

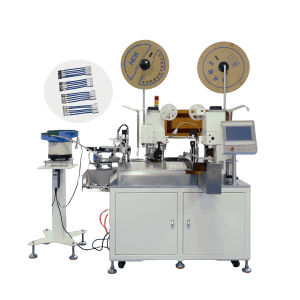

At CableMachineries, we’re more than just a supplier—we’re your automation partner. Here’s what makes us a standout automatic crimping machine factory:

7. Take Action Today

Ready to source from a reliable automatic crimping machine factory? Get a quote, request dual/triple-head demo, or explore our waterproof insertion models:

图2-298x300.png)