What Is a Wire Harness?

What Exactly Is A Wire Harness?

Terminals serve as the points where wires connect to other components. Crimp terminals, insulated terminals, heat-shrink terminals, and solder terminals are among the many types of these small but critical components. Each type is designed for specific applications and environmental requirements. These terminals are then housed in wire harness connectors, resulting in secure, weatherproof connections that are easy to assemble and disassemble as needed.

Sleeves, braided coverings, or specialized tapes wrap around the entire assembly to protect it. This layer protects the internal wires from vibration, abrasion, moisture, and electromagnetic interference, which could disrupt signal transmission and cause system failures.

When compared to loose wiring, the benefits of using wire harnesses are clear. Installation time is significantly reduced because technicians use pre-assembled units instead of individual wires. This organized method virtually eliminates the wiring errors that plague loose-wire installations. The bundled design also provides superior protection against vibration, wear, short circuits, and EMI interference, all of which can damage sensitive electronic systems.

Why Wire Harness Assembly is important.

When compared to the alternative – loose wire installations that cause maintenance nightmares and reliability issues – the importance of wire harness assembly becomes clear. Consider trying to troubleshoot an electrical problem in a system where hundreds of individual wires snake through cramped spaces with no organization or protection. The wire harness assembly eliminates this chaos by establishing logical, traceable electrical connections.

In complex systems such as automobiles or industrial control panels, cable organization becomes critical for both functionality and safety. A modern automobile contains over 100 separate electrical circuits that control everything from engine management to entertainment systems. These systems could not be manufactured or serviced reliably without proper wire harness organization.

One of the primary benefits of wire harness assemblies is their ease of installation. Technicians can install complete electrical subsystems in minutes rather than hours, lowering labor costs and increasing consistency. Harnesses are pre-assembled, so connections are made in controlled factory environments rather than in the field, where conditions may be less than ideal.

Wire harness organization improves maintenance and repair operations significantly. When problems arise, technicians can quickly trace circuits and identify issues without having to follow individual wires through intricate routing paths. This improved serviceability cuts downtime and repair costs while increasing system reliability.

Cost control includes more than just installation and maintenance. Wire harness assemblies enable manufacturers to standardize electrical systems across multiple product lines, reducing inventory requirements and simplifying procurement. Harnesses’ organized nature also allows for better quality control during manufacturing, detecting potential issues before they reach the field.

How Is a Wire Harness Kit Made? Key steps and machines

Design and Engineering

Every wire harness kit begins with meticulous design and engineering work, which ultimately determines its success or failure. Engineers create detailed schematics and routing diagrams using specialized EDA (Electronic Design Automation), CAD (Computer Aided Design), and 3D modeling tools such as SOLIDWORKS Electrical. This design phase produces critical documentation such as Bills of Materials (BOMs), wire length specifications, and detailed assembly drawings that guide the manufacturing process.

During this phase, the engineering team must take electrical requirements, mechanical constraints, environmental conditions, and manufacturing limitations into account. They specify wire gauges, insulation types, connector styles, and protective coverings based on the application’s specific requirements. This initial investment in design pays dividends throughout the manufacturing process and the harness’s operational lifespan.

Precision starts with cutting and stripping wires to exact specifications in the manufacturing process. Modern wire harness manufacturing is heavily reliant on automated wire cutting and stripping machines that can process hundreds of wires per hour with remarkable precision. These machines cut conductors to exact lengths and strip insulation from both ends, preparing them for terminal attachment.

CableMachineries’ cutting and stripping equipment can handle wire gauges ranging from 32 AWG to 4/0 AWG, with length tolerances measured in millimetres. This precision ensures that every wire fits perfectly in its intended location, with no excess length to cause routing problems or insufficient length to prevent proper connections.

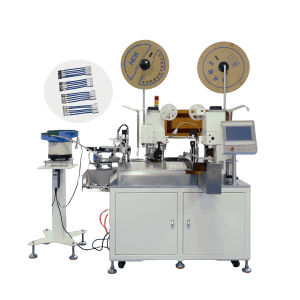

Terminal crimping and soldering

The next critical step is to crimp or solder terminals to the wire ends that have been prepared. Automatic crimping machines use precisely controlled pressure to form gastight connections between terminals and conductors. These machines can be programmed for various terminal types and wire gauges, ensuring consistent connection quality throughout production runs.

Soldered connections are required in some applications for maximum reliability or to meet specific environmental requirements. Hybrid harness manufacturers combine multiple processes in a single machine, performing cutting, stripping, and terminal attachment operations in order. Advanced systems can even perform automatic insertion and extraction for specialized connectors.

Connector Insertion and Module Assembly

After terminals are connected to wires, the assembly process progresses to connector insertion and module assembly. Trained technicians or automated insertion equipment insert terminated wires into connector housings in accordance with detailed assembly drawings. To ensure reliable connections, this step requires careful attention to pin assignments and proper seating.

Automated insertion equipment can handle high-volume production runs with consistent quality, but complex or low-volume harnesses require manual assembly. The choice between automation and manual assembly is determined by production volume, complexity, and cost.

Bundling and Sleeves

Individual wires are organized into harness assemblies through bundling and sleeving. To create neat, protective bundles, technicians use cable ties, spiral wrap, heat shrink tubing, braided sleeves, and specialized tapes. High-performance applications may necessitate additional safeguards such as heat-sealed sleeves or specialized shielding materials.

This step necessitates a high level of skill and experience in order to create harnesses that route properly, resist environmental stresses, and remain organized throughout their operational life. The bundling process also includes strain relief elements, which prevent stress concentration at connection points.

Testing & Quality assurance

Before it leaves the manufacturing facility, each wire harness kit is rigorously tested. Electrical testing includes continuity checks to ensure that all connections are correct and insulation resistance testing to ensure that circuits are properly isolated. Pull testing confirms that terminal connections can withstand the mechanical stresses encountered during installation and operation.

Functional testing may include actual operation in simulated conditions to ensure that the harness works as intended. Advanced testing equipment can run hundreds of electrical tests in seconds and provide detailed documentation of harness performance and specification compliance.

What to Expect with Automation vs. Manual Assembly

The wire harness manufacturing industry is evolving as automation technology advances, but manual assembly continues to dominate many aspects of production. Understanding the balance of automated and manual processes helps to explain current manufacturing capabilities and future trends.

Manual assembly remains the primary method for complex harness integration, branch routing, sleeve installation, and specialized bundling operations. These tasks necessitate human judgment, dexterity, and problem-solving skills, which current automation technology cannot cost-effectively replicate. Skilled technicians can adapt to design changes, handle unusual routing requirements, and perform quality checks that automated systems may overlook.

However, automation trends continue to accelerate. Companies such as Komax have created sophisticated Zeta and Omega series harness assembly platforms capable of performing cutting, crimping, insertion, and marking operations with minimal human intervention. These systems excel at high-volume manufacturing of standardized harnesses, where consistency and speed are more important than flexibility.

The comparison of automated and manual methods reveals distinct advantages for each. For large production runs, automation provides greater consistency, faster production rates, and lower per-unit costs. Automated systems also reduce labor requirements and can run continuously with little supervision.

Manual assembly is ideal for small batch production, complex custom harnesses, and applications that require frequent design changes. Skilled technicians can handle unusual requirements, perform complex routing operations, and respond to engineering changes without the need for costly reprogramming or retooling.

Most modern harness manufacturers employ hybrid approaches, which combine automated equipment for standardized operations with manual assembly for complex or custom work. This balanced approach maximizes cost and flexibility while maintaining quality.

Conclusion

Understanding what a wire harness is and how it is made provides important information about the electrical systems that power our modern world. From the simplest radio wire harness to complex automotive wiring systems, these well-organized assemblies enable dependable electrical connections in a wide range of applications.

Precision engineering, advanced machinery, and skilled craftsmanship are all used in the manufacturing process to create products that must perform reliably for years in harsh conditions. Quality wire harnesses, whether produced using automated systems or manual assembly, are critical components that enable everything from transportation to communication systems.

The manufacturing equipment and processes used in wire harness production have a significant impact on both quality and cost. Investing in proper machinery, skilled personnel, and quality control systems yields benefits such as increased product reliability, lower warranty costs, and higher customer satisfaction.

If you’d like to learn more about wire harness production machinery, visit CableMachineries (https://www.cablemachineries.com/product-category/wire-processing/) and contact us for a customized solution. Our knowledgeable staff can assist you in selecting the appropriate equipment for your specific production and volume needs.

Whether you’re new to wire harnesses or looking to improve your manufacturing capabilities, understanding these fundamental concepts is the first step toward making informed decisions about electrical system design and production. We encourage you to contact us if you have any questions or want to discuss how our equipment can help you meet your wire harness manufacturing goals.

Ready to source from a reliable automatic crimping machine factory? Get a quote, request dual/triple-head demo, or explore our waterproof insertion models:

图2-298x300.png)