⚙️ What Is a Wire Stripper Cutting Bending Machine? (2025 Full Guide)

Focus keyphrase: wire stripper cutting bending machine

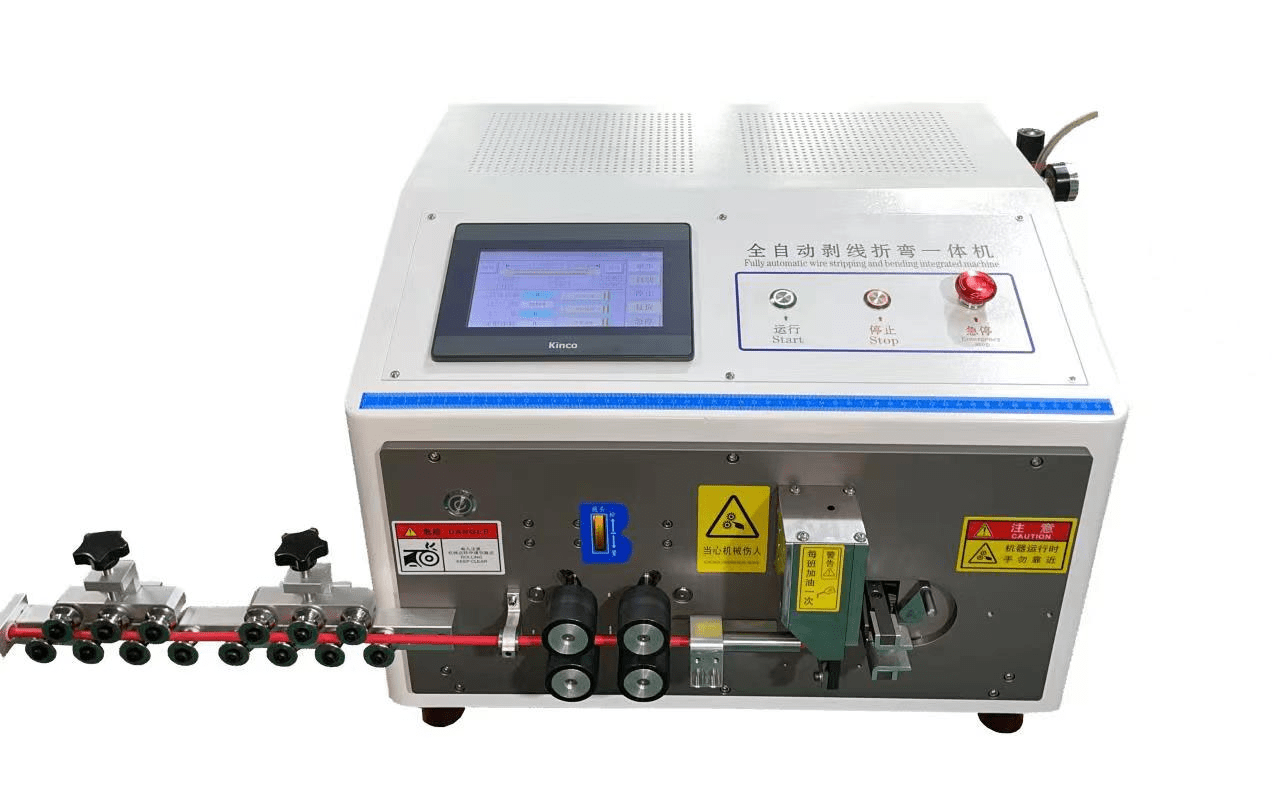

In modern wire harness processing, precision and automation are everything. A wire stripper cutting bending machine integrates three essential steps—cutting, stripping, and bending—into a single efficient operation. This guide will walk you through what it is, how it works, and how your business can benefit from using one.

“`🔧 What Does a Wire Stripper Cutting Bending Machine Do?

This type of automation machine is designed to:

- Cut wire to precise lengths

- Strip insulation without damaging the core

- Bend wires to pre-programmed angles or shapes

They are essential in electrical cabinet manufacturing, automotive wiring, and other industrial fields that require high wire volume and complex assembly processes.

🧩 Key Components and Their Roles

- Cutting Blades – High-hardness alloy blades ensure sharp and clean cuts

- Stripping Unit – Precisely removes insulation with customizable length control

- Bending Fixture – Shapes wires to fit connectors or circuit board terminals

- Stepper Motor System – Drives feeding and bending with consistent torque

- Touchscreen Control Panel – For parameter input, program recall, and diagnostics

🏭 Our Manufacturing & Quality Process

Each machine is built in our precision factory using top-grade components. Before delivery, we run a full diagnostic and performance test. Packaging is done with reinforced wooden crates to ensure safety during international shipment.

🛠️ Maintenance Tips

To keep your machine in top shape:

- 🗓️ Daily: Remove wire debris and clean blades

- 🗓️ Weekly: Lubricate feeding and bending shafts

- 🗓️ Monthly: Check motor noise, recalibrate blade alignment

💡 Common Problems & Solutions

- Wire not fully stripped? ➤ Adjust blade depth or change worn blades

- Bending angles inconsistent? ➤ Recalibrate fixture arm or check motor torque

- Cutting too long/short? ➤ Re-enter correct wire length in control panel

🚀 Why Choose Our Machines?

- 🇨🇳 Built by a trusted Chinese factory with OEM support

- 📈 Proven to reduce cycle time by 30% compared to manual setups

- 🌍 Global shipping and remote technical support