Ultimate Troubleshooting Guide: Wire Cutting & Crimping Machines – Solve 95% of Common Issues (2025 Edition)

Wire cutting and crimping machines are vital for high-speed, high-accuracy wire harness processing in industries like automotive, appliances, control cabinets, and telecom. However, issues in blade wear, feeding misalignment, or terminal deformation can lead to operational downtime.

🔧 Common Issues & How to Fix Them

Q: Why are wire cutting lengths inconsistent?

- Feeding wheel pressure is low → Tighten the spring tension.

- Wire slipping during feed → Clean feed rollers and adjust tension.

- Blade misalignment → Re-calibrate the cutting blade mechanism.

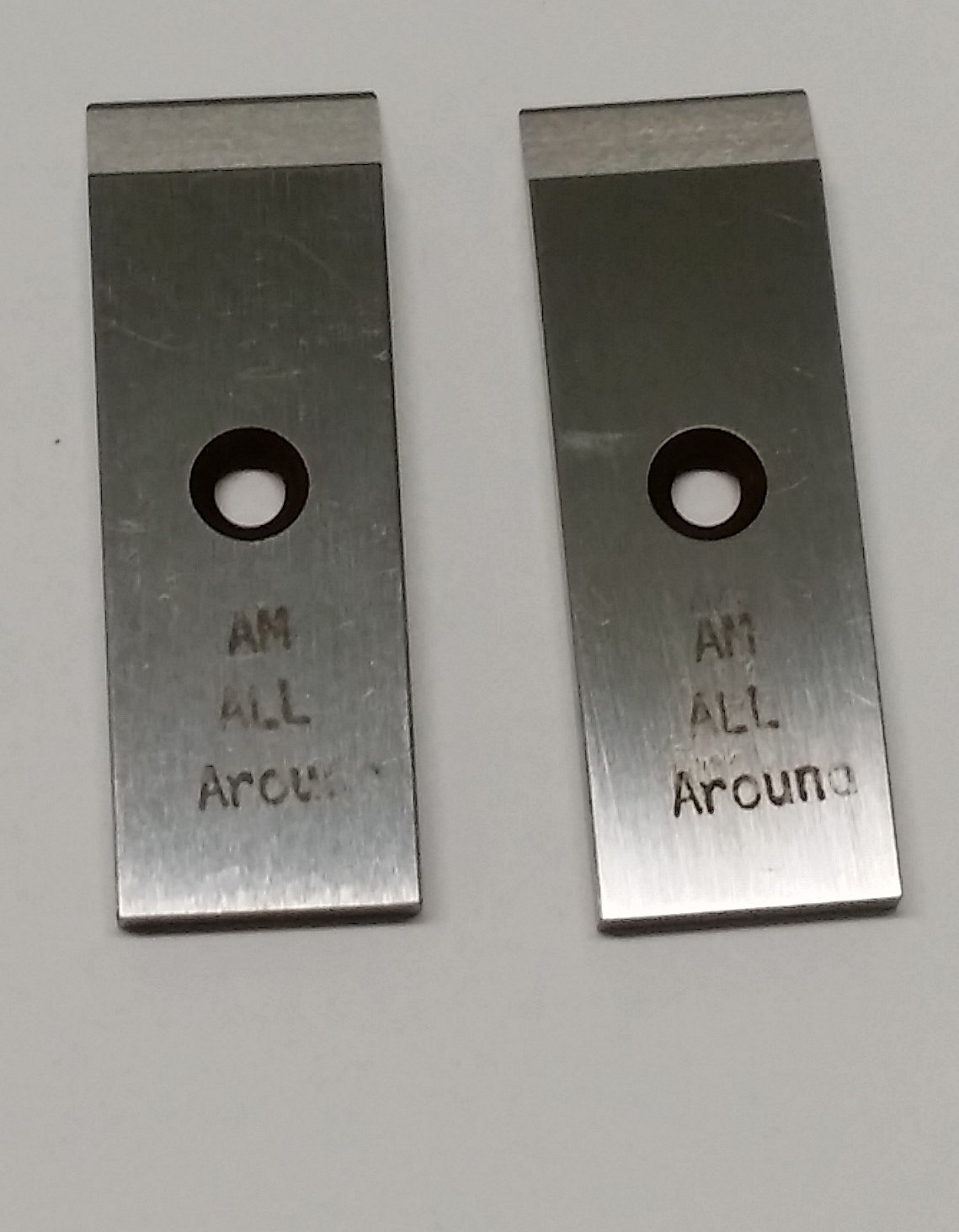

Q: Wire core damaged during stripping?

- Blade depth too deep → Adjust stripping value on screen.

- Blade edge worn → Inspect and replace with new crimping blade.

- Improper pull-back value → Modify retraction parameters.

Q: Back-end stripping fails – why?

- Jaws too loose → Adjust gripping tension.

- Stripping wheel not centered → Re-calibrate stripping axis.

- Blade cannot complete stroke → Clean blade holder from debris.

Q: Terminal crimping fails or is loose?

- Die position error → Adjust crimping die holder position.

- Insufficient air pressure → Check compressor feed and regulator.

- Mismatch in wire size and terminal → Verify crimp tool specifications.

Q: Motor overload or abnormal vibration?

- Feeding jam or blocked encoder → Inspect roller path.

- Drive belt loose → Re-tighten or replace belt.

- Controller error → Reset or replace PLC card if needed.

📦 Factory Assembly and Packaging Quality

All our wire cutting and crimping machines undergo factory pre-testing, full calibration, and safety checks before packaging. Machines are secured in reinforced wooden crates to ensure damage-free delivery worldwide.

⚙️ Pro Tips to Enhance Performance

- Use high-hardness alloy blades to double the replacement cycle.

- Lubricate feeding gears weekly to prevent motor strain.

- Upgrade to smart PLC models with auto-diagnosis and error code display.

- Check jaw clamping force using a pressure gauge monthly.