By Leo Zhang, an automation engineer with 12 years in wire harness manufacturing and cable machinery optimization.

1. Why Wire Processing Automation Is No Longer Optional

I’ve worked with wire processing equipment for over a decade—long enough to see how much time and consistency get lost when everything is done manually. Whether it’s in a car factory, a control panel shop, or a wiring harness line, people are still surprised by how much difference one good machine can make.

If you’re still doing wire cutting, stripping, and crimping in separate steps—or worse, by hand—you’re leaving both money and quality on the table. A reliable wire cutting, stripping, and crimping machine doesn’t just save time. It gives you repeatable precision, reduces human error, and lets your team focus on assembly instead of prep work.

Wire harness quality standard IPC/WHMA-A-620

2. What Exactly Is a Wire Cutting, Stripping & Crimping Machine?

In simple terms, it’s your wire shop’s most efficient employee.

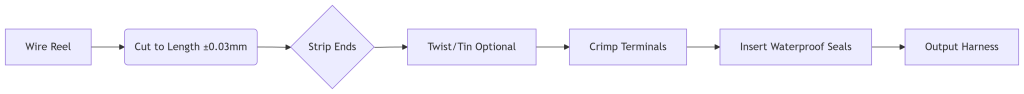

These machines automatically:

Cut wire to custom lengths;

Strip insulation on one or both ends;

Crimp terminals securely and consistently.

More advanced models (like some of the ones I help configure for our customers) can also twist, tin, or insert waterproof grommets—all in one uninterrupted workflow.

3. Types of Machines: Which Is Right for You?

| Machine Type | Who It’s For | Good Examples |

|---|---|---|

| Manual Tools | Small repairs or DIY | Handheld crimpers |

| Benchtop Semi-Automatic | Workshops with modest output | KK-500M, KK-501 |

| Fully Automatic Systems | High-output factories, OEM lines | KKD3, KKD6, DWGSF2 |

4. Quick Product Comparison Table

| Feature | KKD3 Dual-End Crimping |

KKD6 Grommet + Crimping |

KK-503N Flat Wire Specialist |

|---|---|---|---|

| Wire Range | AWG14–28 | AWG28–16 | Up to 6mm² flat |

| Functions | Cut, Strip, Twist, Crimp | Cut, Strip, Crimp, Grommet, Tin | Cut, Strip, Twist |

| Precision | ±1mm + 0.2% | ±0.1–0.2mm | ±0.002 × L |

| Speed | 1,400 pcs/hr | 1,200 pcs/hr | Up to 3,000/hr |

| Use Case | Auto harnesses | Waterproof cables | Flat cable prep |

5. How I Help Clients Choose the Right Machine

Every week I get messages from factory managers asking which machine is “best.” But honestly, that depends on what you’re producing.

Here’s what I usually ask them:

What kind of wire are you working with (round, flat, shielded)?

Do you need both ends processed—or just one?

Any special terminals? Waterproof? Flag-type? Tin-dipped?

What’s your daily output goal?

What’s your available floor space and power setup?

And lastly: What’s your budget vs. expected ROI?

If you can answer those, it’s much easier to pick the right setup.

Automotive wire harness solutions

6. Features That Really Matter (From Experience)

After years of helping clients install and tune these machines, here’s what I’ve learned actually makes a difference:

Precision stepper motors (at least 0.03mm resolution)

Auto wire jam detection (saves so much downtime)

Touchscreen interface for quick job changes

Memory presets—essential if you run multiple wire types

Servo-driven crimping force for consistent pull-out strength

And don’t underestimate something as simple as easy blade replacement. When it’s a 2-minute swap instead of 20, your uptime goes up fast.

7. Why Buy from Us?

I work for a factory—not a reseller. That means:

✅ Machines are built in-house

🔧 We test each unit before shipping

📦 We export globally

🎥 You can actually see our machines working on our YouTube channel

And when you contact us, you’ll talk to someone who knows these machines.

8. FAQ: Questions I Get All the Time

| Question | Answer |

|---|---|

| What’s the minimum wire size supported? | As small as AWG32 (0.03mm²), depending on the machine model. |

| Can these machines handle waterproof cables? | Yes. KKD6 and DWGSF2 models support waterproof grommet insertion and sealed crimps. |

| Is operator training necessary? | Basic training takes 2–3 hours. We also provide English manuals and remote video support. |

| Can one machine handle various wire lengths? | Absolutely. Most machines include memory presets and batch switching support. |

| What’s the lead time for delivery? | Usually 7–14 days. Custom-built configurations may take longer. |

9. Final Thoughts: Cut Smarter, Not Harder

In 2025, there’s no reason to be stuck in manual mode. If you’re serious about increasing output and cutting labor waste, a wire cutting, stripping, and crimping machine should be your next move.

And if you’re still unsure? Just send me a wire spec sheet—I’ll help you figure it out.