Why Wire Stripper Crimpers Are Revolutionizing Auto Harness Work

Introduction: Smarter Wire Processing in Modern Factories

In today’s industrial environment, every second counts. From automotive harness factories to renewable energy projects and aerospace wiring, wire processing has become one of the most critical — yet overlooked — stages of production.

Traditionally, operators had to switch constantly between a manual wire stripper and a separate crimping machine. This not only slowed down production but also increased the risk of human error.

Take the case of an automotive harness workshop in Michigan: by upgrading to a multi function wire stripper crimper, the factory reduced tooling changeover time by 37% and doubled its daily throughput — all without hiring extra staff.

This example shows why more North American manufacturers are embracing automation. Consistency, speed, and compliance with standards such as IPC/WHMA-A-620 are driving this transformation.

What Is a Wire Stripper Crimper?

A wire stripper crimper combines two vital processes in one machine:

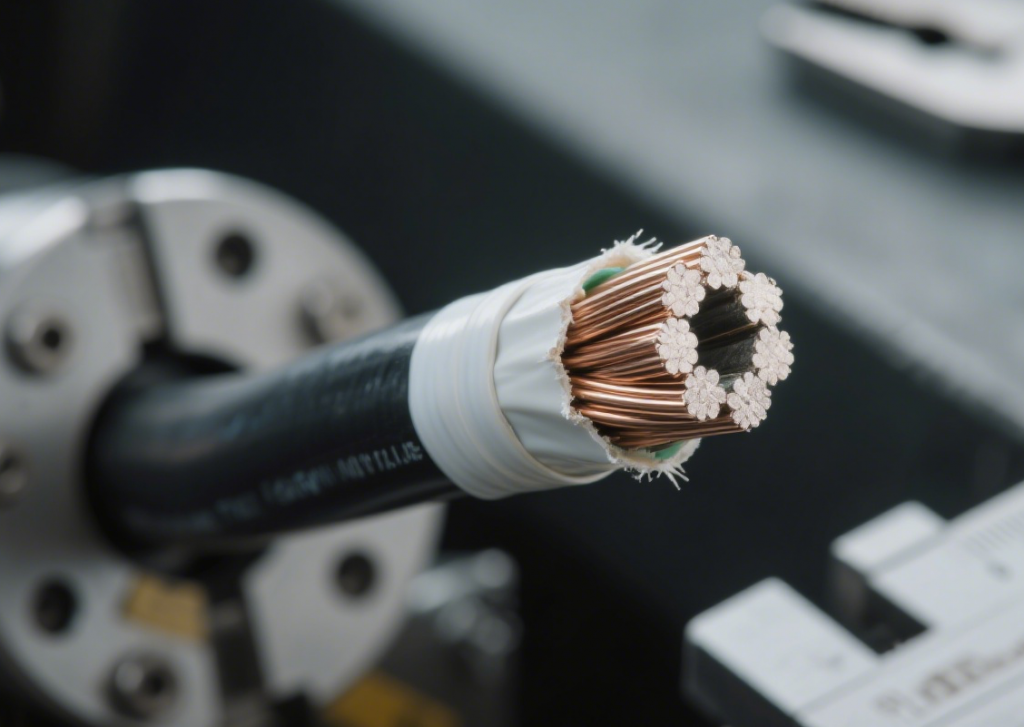

Stripping – removing insulation from wires with micron-level precision, without damaging copper strands.

Crimping – pressing a terminal onto the stripped wire with high force for a secure electrical connection.

While manual tools depend heavily on operator skill, modern multi function wire stripper machines use hydraulic crimping units (up to 10 kN pressure), servo motors, and programmable depth settings. This allows flawless processing of everything from fine signal wires to heavy duty wire stripper applications such as 4 AWG and 6 AWG power cables used in renewable energy systems and EV charging stations.

The Limitations of Manual and Single-Function Tools

Factories relying on standalone crimpers or manual strippers face three main issues:

Time Loss – constant tool changes waste hours each week.

Error Risk – hand handling often leads to under-crimped terminals or insulation damage.

Scaling Problems – throughput limits prevent growth in high-volume production.

Even semi-automatic wire strippers (600–1,000 wires/hour) fall short in demanding environments. In contrast, a multi function wire stripper crimper handles 2,000–5,000 wires/hour, completing both stripping and crimping in a single cycle.

Key Features of Modern Multi-Function Wire Stripper Crimpers

When evaluating options, procurement managers should focus on features that separate industrial-grade machines from entry-level tools:

Modular Tooling Systems – adapt to wire sizes from 0.5 mm² to 16 mm² with minimal downtime.

Hydraulic Crimping Units – up to 10 kN pressure ensures secure heavy-duty terminal connections.

Multi-Layer Stripping – handle coaxial, Teflon-coated, and shielded wires.

Touchscreen PLC Interface – store profiles for quick changeovers.

Integrated Detection Sensors – confirm terminal presence and crimp quality.

Durability and Safety – steel components, self-calibration, and safety doors for 24/7 operations.

By meeting UL-certified requirements (UL Standards), these machines reduce rework and ensure long-term reliability.

For marine electronics manufacturers requiring IP69K compliance:

Our WP-200 module integrates:

Silicone sealant injection with 0.01ml precision

UV curing tunnel (365nm wavelength)

Post-assembly pressure testing at 3 bar

Result: 100% seal integrity

Explore waterproof crimping technology

ROI: Multi-Function vs Single-Function Machines

One of the strongest selling points is the return on investment (ROI).

| Machine Type | Cost | Throughput | Operators | ROI Potential |

|---|---|---|---|---|

| Manual Wire Stripper | $20–50 | ~200 wires/hour | 1 per tool | Minimal |

| Semi-Automatic Stripper | $500–$2,000 | 600–1,000 wires/hour | 1 per machine | Moderate |

| Automatic Multi-Function Wire Stripper Crimper | $5,000+ | 2,000–5,000 wires/hour | 1 per 2–3 machines | ROI in months |

For a plant processing 10,000 cables per day, automation can save up to $80,000 annually in reduced labor and scrap.

Applications Across Key Industries

Automotive Harness Production

Wire stripper crimpers simplify the production of complex harnesses for EV and hybrid vehicles. With modular dies and automation, factories cut downtime while ensuring compliance with automotive electrical safety standards.

Renewable Energy

Solar and wind projects demand heavy duty wire strippers capable of handling thick, large-diameter power cables. As emphasized by the U.S. Department of Energy’s Solar Manufacturing Guidelines, cable reliability is a cornerstone of renewable infrastructure.

Aerospace and Defense

Precision is non-negotiable. Compliance with FAA Wiring Safety Programs and NASA Electrical Design Guidelines requires automated stripping to avoid strand damage that can lead to failures.

Telecommunications

With 5G and fiber optics expanding, IEEE standards demand precise coaxial stripping. Multi function wire strippers with multi-layer capability ensure signal integrity at high frequencies.

Why Automotive Workshops Prefer Multi-Function Wire Stripper Crimpers

Frequent die and stripper head changes are a major time drain in auto harness assembly. Multi function systems with modular tooling cut this downtime dramatically.

Case studies show consistency in crimps across different gauges and reduced setup time by 37%. This is why wire stripper crimpers are rapidly becoming the default choice in automotive workshops worldwide.

Buyer’s Guide: How to Choose the Right Wire Stripper Crimper

When selecting a machine, procurement teams should evaluate:

Wire Range – Can it process both fine wires and heavy-duty cables up to 30 mm²?

Throughput – Does it align with production targets?

Integration – Can it work with automatic feeders or cutting units?

After-Sales Support – Is local service and spare part availability guaranteed?

👉 Explore Cable Machineries’ terminal crimping machines for customizable solutions designed for North American and global standards.

Conclusion: The Future of Wire Processing in Industry 4.0

As factories embrace Industry 4.0, multi function wire stripper crimpers are no longer optional upgrades — they are competitive necessities. From telecom networks to renewable energy and automotive harness assembly, these machines ensure speed, consistency, and compliance.

By reducing waste, boosting throughput, and maintaining international standards, wire stripper crimpers are setting the new benchmark for industrial productivity.