Why Wire Strippers Still Matter

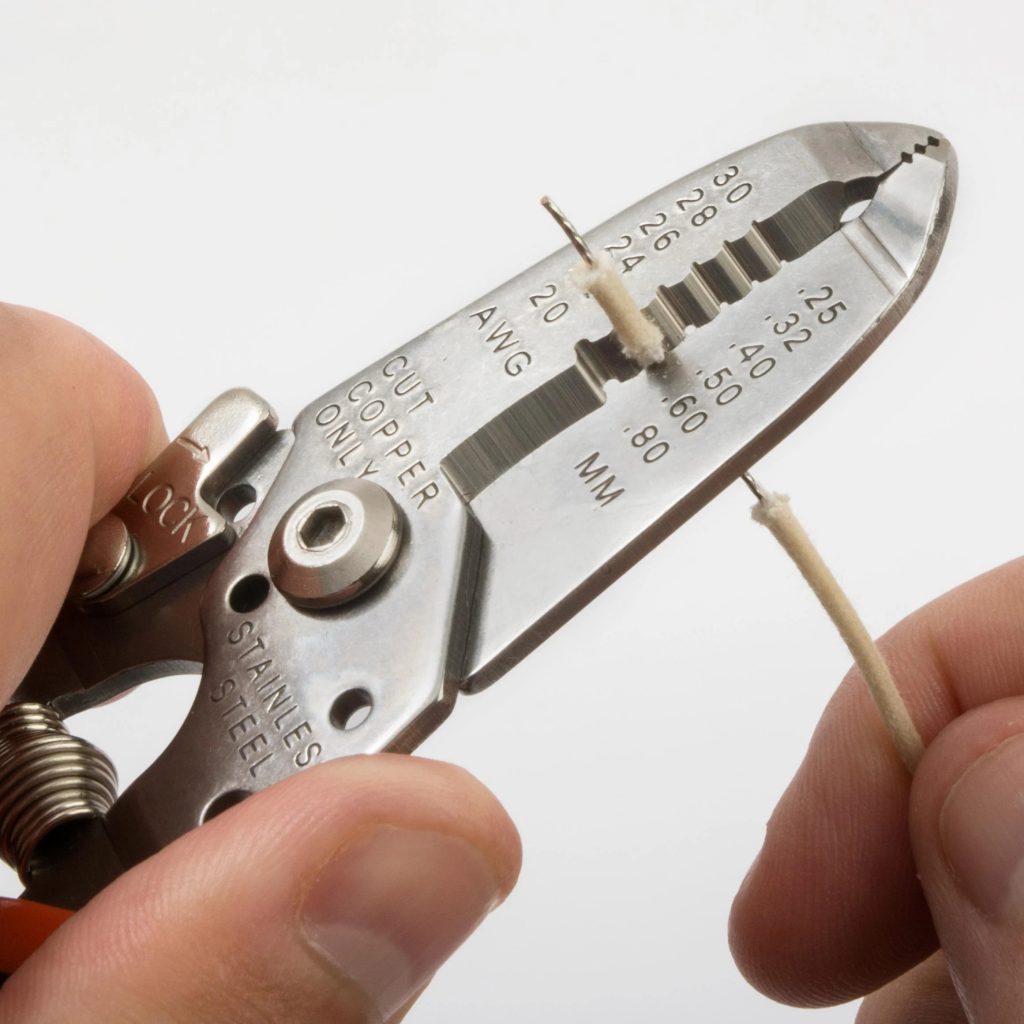

If you’ve spent time around cables, you already know the humble wire stripper is more important than it looks. Get it wrong, and you nick copper, weaken the joint, or waste hours fixing mistakes. Get it right, and you’ve got a clean connection that saves time, money, and headaches down the line.

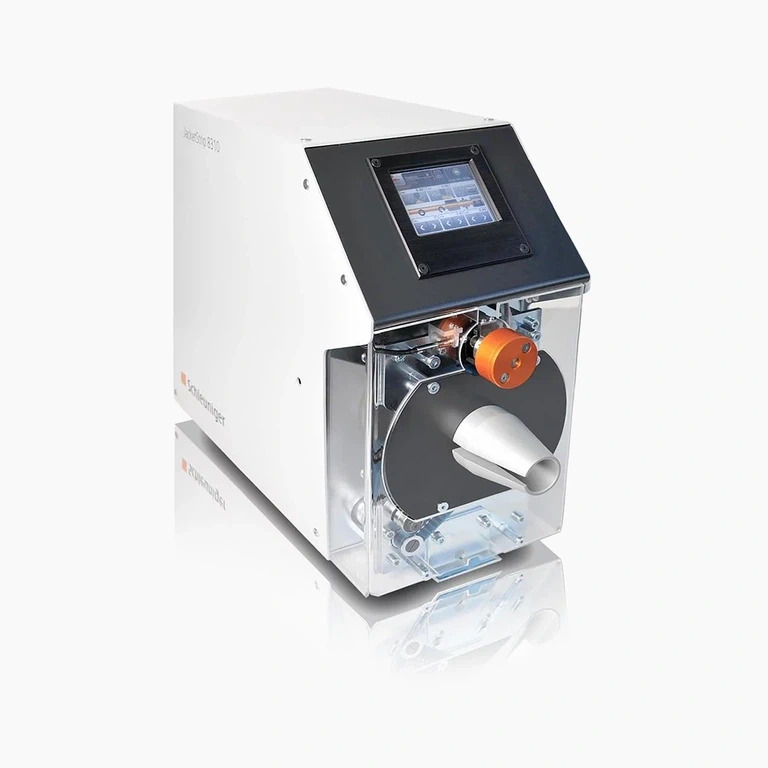

Today, many shops are moving beyond simple wire strippers toward a dedicated wire stripping machine. The difference is night and day. Below, I’ll share the top five applications where machines shine, why hand tools aren’t going away, and a few lessons from the field.

1. High-Volume Cable Prep in Automotive & EV Harnesses

In auto harness workshops or EV cable production, speed matters. Every delay in stripping or crimping wires bottlenecks the entire assembly line.

That’s where wire stripping machines pull ahead. With programmable settings, machines like the KK-502 can crank through thousands of cables in a shift while holding tolerances tight. Scrap drops, and operators aren’t wasting time swapping tools.

Compare that to a manual wire stripper: it’s fine for a few dozen wires, but after hundreds, fatigue sets in and mistakes multiply. For volume production, the ROI on automation is obvious.

2. Copper Recycling & Scrap Recovery

Anyone who’s tried to strip old motor windings or heavy power cables knows the pain of doing it by hand. Wire strippers just aren’t built for that kind of grunt work.

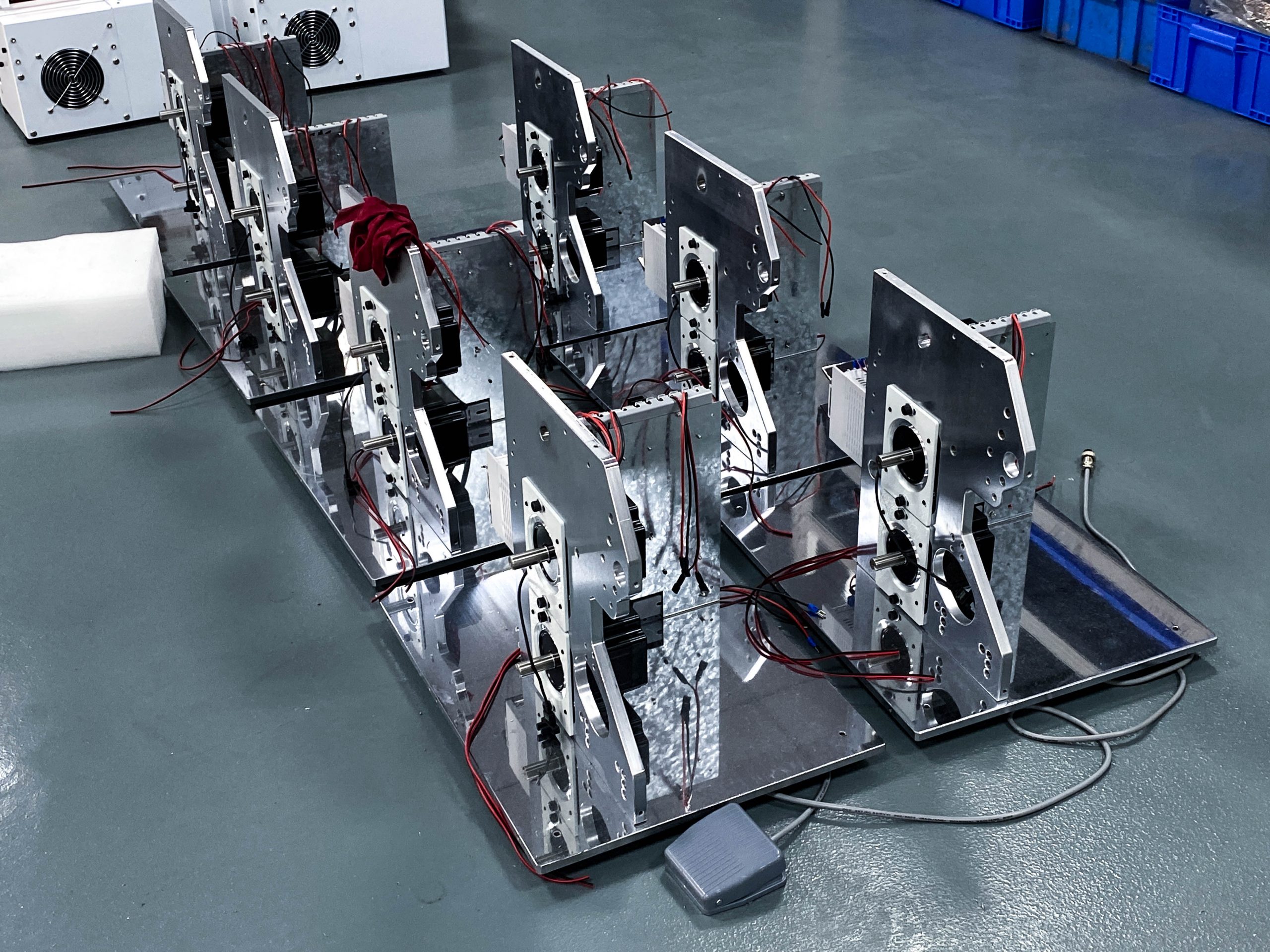

A wire stripping machine, on the other hand, slices insulation cleanly, speeds up copper recovery, and pays for itself quickly in a recycling yard. That’s why scrap processors often run multiple machines side-by-side. Less manual labor, more recovered copper, better profit.

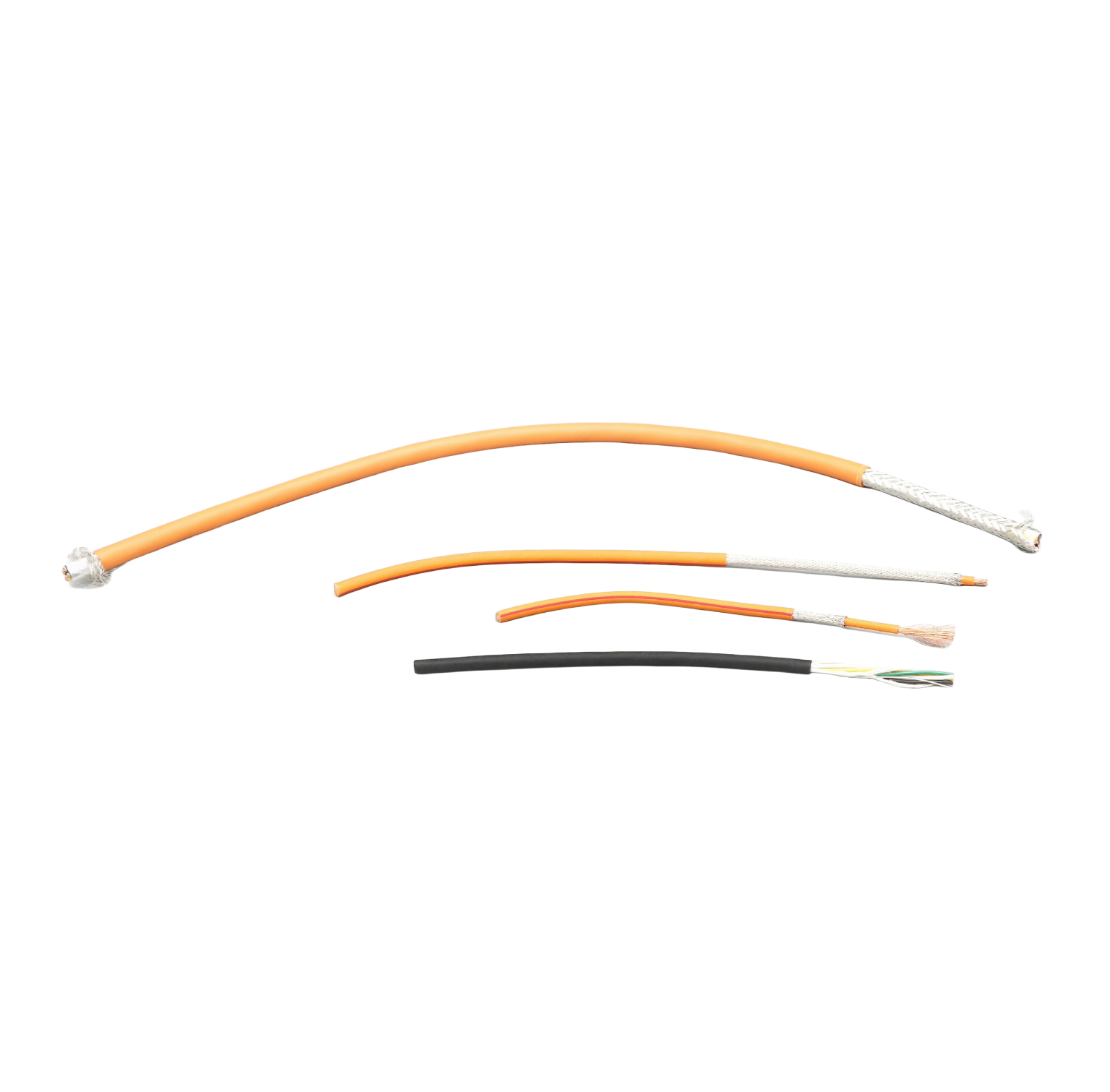

3. Handling Specialty Cables (Coax, Shielded, Multi-layer)

Not all wires are equal. Coaxial and shielded cables demand precision—you only want to take off the insulation you’re targeting, not cut into shielding or nick conductors.

Hand wire strippers are useful for small test runs, but when consistency matters—think aerospace wiring or telecom coax—an adjustable wire stripping machine is the safer bet. Machines with programmable blade depths can strip multiple layers in one cycle, something nearly impossible to match by hand.

4. Prototyping & Small-Batch Flexibility

Even in big factories, there are times when you’re only prepping a dozen wires for a prototype. Setting up a machine might not be worth it. That’s when a simple wire stripper tool is still king.

But when small batches turn into repeat jobs, a wire stripping machine pays off. The ability to switch settings quickly means you don’t waste hours readjusting. Many shops keep both on hand—hand strippers for quick tests, machines for repeat runs.

5. Safer, Cleaner Results for Compliance

Industry standards (UL, IPC/WHMA-A-620) don’t leave much room for sloppy work. Damaged strands or uneven strip lengths can kill product quality and even create safety risks.

Machines reduce that risk. A good wire stripping machine will hold depth within fractions of a millimeter, job after job. No guessing, no second-guessing. For factories needing compliance documentation, that kind of consistency is gold.

Hand wire strippers still do the job—if the operator is skilled and careful. But machines give you repeatability without relying on perfect technique every time.

Wire Stripper vs. Wire Stripping Machine: Quick Comparison

| Feature | Hand Wire Strippers | Wire Stripping Machines |

|---|---|---|

| Speed | Dozens–hundreds per hour | Hundreds–thousands per hour |

| Consistency | Operator-dependent | Very consistent once set |

| Setup | Instant | Requires calibration |

| Best For | Field work, prototypes, low volume | Production runs, compliance work, recycling |

| Cost | Low upfront | Higher upfront, fast ROI |

Field Example: EV Harness Upgrade

One of our EV clients came to CableMachineries struggling with copper strand damage and uneven strip lengths using only hand wire strippers. Operators were wasting hours re-doing cables, and scrap costs were climbing.

We installed a KK-502 wire stripping machine. Within weeks:

Scrap fell from 5% to under 1%

Strip length tolerances held at ±0.1 mm

Throughput tripled, with no additional staff

That’s the difference automation can make.

Choosing the Right Tool for the Job

When picking between wire strippers and a wire stripping machine, ask yourself:

How many wires per day? If it’s a few dozen, stick to hand tools. If it’s thousands, go automated.

What type of wire? Shielded, thick, or multi-layer wires are better handled by a machine.

What’s the tolerance? Compliance standards usually demand machine-level precision.

Budget? A good machine costs more upfront but pays off fast in labor and scrap savings.

For a closer look at industrial-grade machines, visit our Terminal Crimping Machine Category where you’ll find solutions that integrate stripping, crimping, and even tinning.

5. Industry-Specific Solutions

Final Word

Whether you’re a DIY tinkerer, a recycling yard operator, or running an automotive harness plant, stripping insulation cleanly is non-negotiable.

Wire strippers are quick, simple, and perfect for light jobs.

Wire stripping machines are faster, safer, and more consistent for serious production.

At CableMachineries, we’ve seen how upgrading to automation transforms output, cuts waste, and improves compliance. If you’re serious about scaling, investing in the right machine could be one of the smartest moves you make this year.