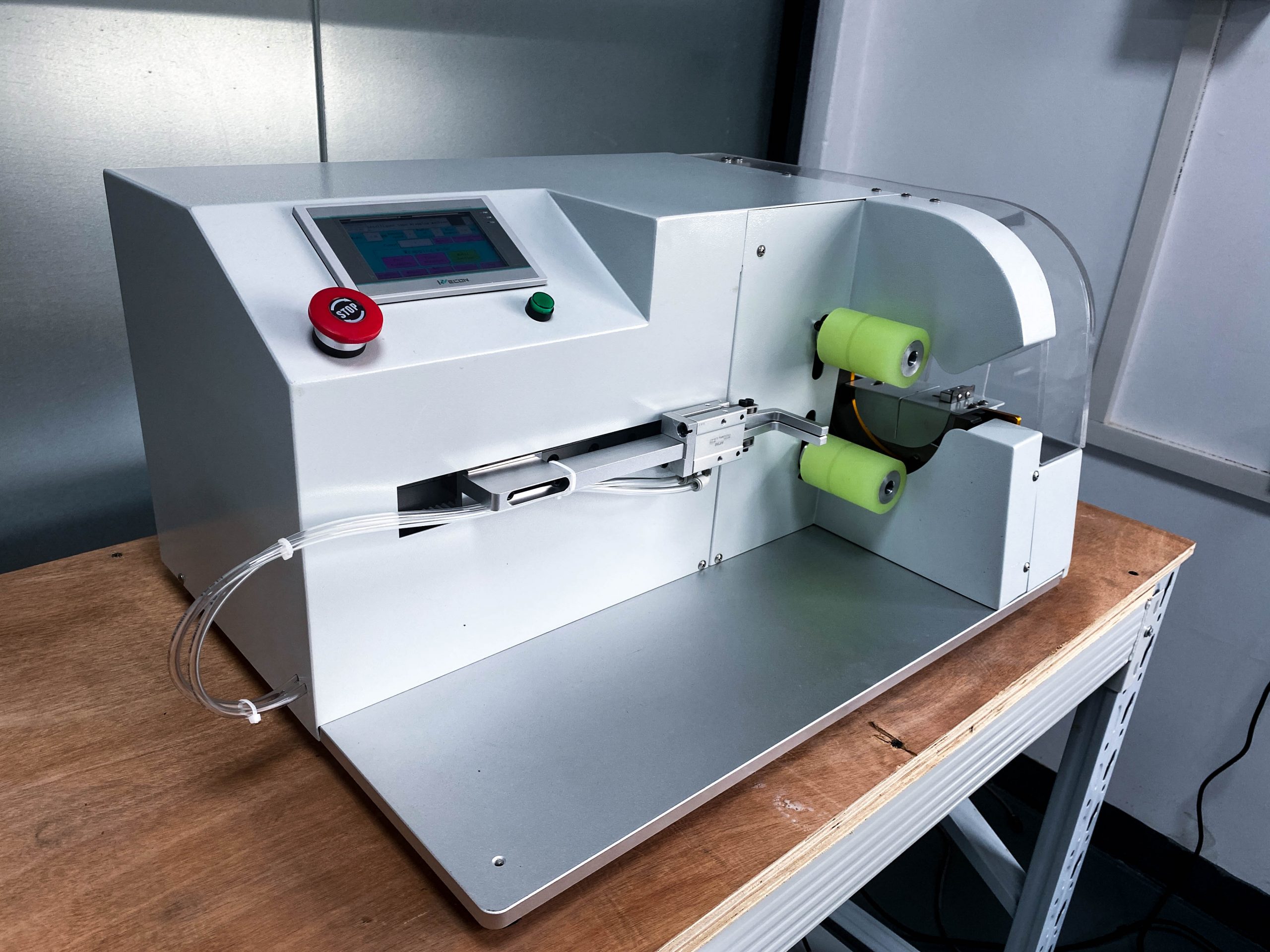

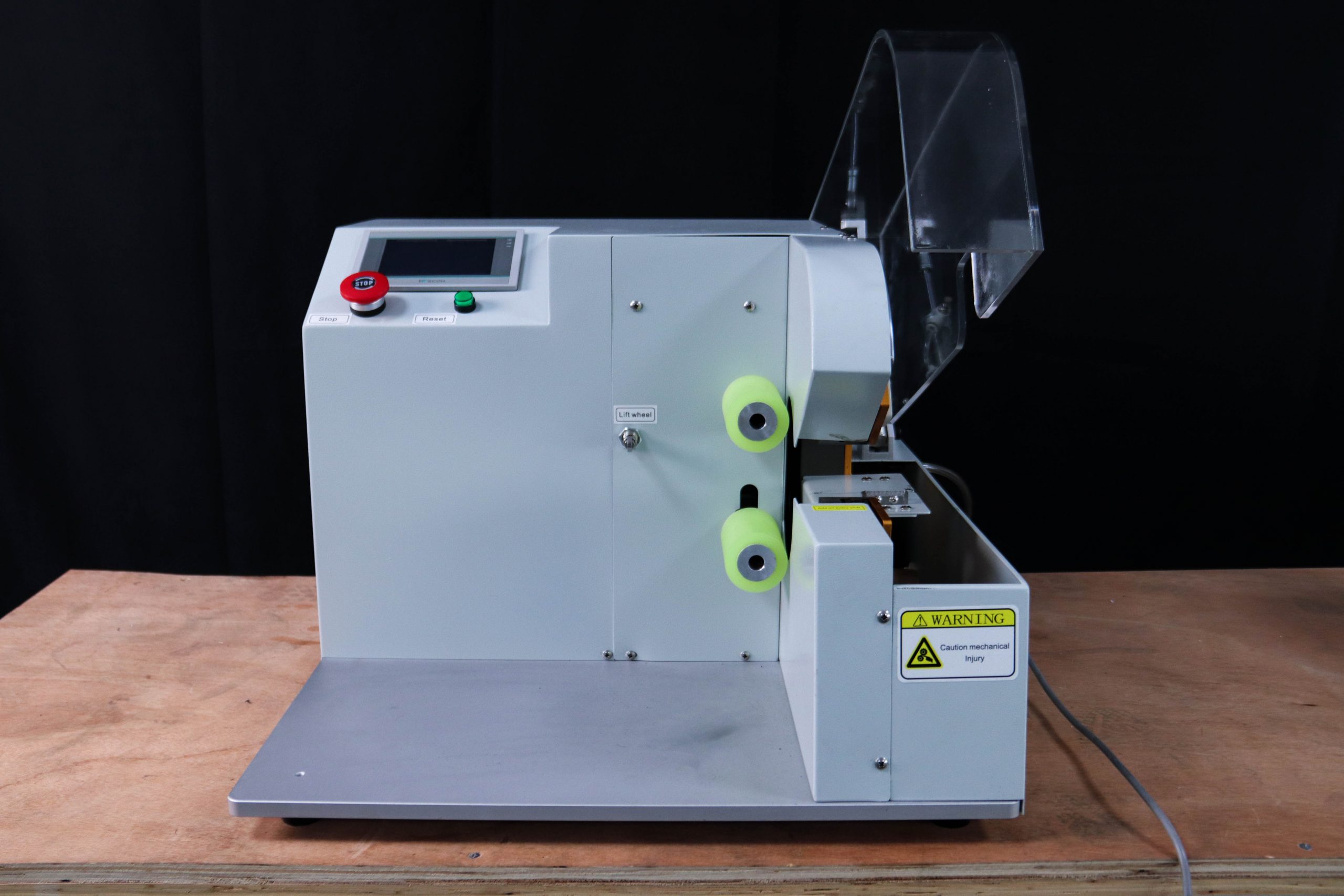

Tube Shrink Wrap Machine – Precision Cable Tubing & Wire Harness System

The tube shrink wrap machine is a critical component in modern wire harness manufacturing. It automates heat-shrink tubing application, ensuring clean sealing, abrasion protection, and uniform insulation. Compared to manual methods, this shrink wrap machine wire solution reduces labor, improves reliability, and achieves consistent quality.

What Is a Tube Shrink Wrap Machine?

A shrink wrap wire machine — also called a heat-shrink tubing machine — uses heat to shrink tubing tightly around cables, offering protection from moisture, abrasion, and vibration. The process results in a sealed, professional finish with precise tension control, ideal for industrial and automotive applications.

How It’s Used in Industry

- Automate tubing placement and heat sealing on millions of wires

- Ensure consistent insulation on connectors, junctions, and repairs

- Integrate with wire cutters, crimpers, and automation cells for turnkey production

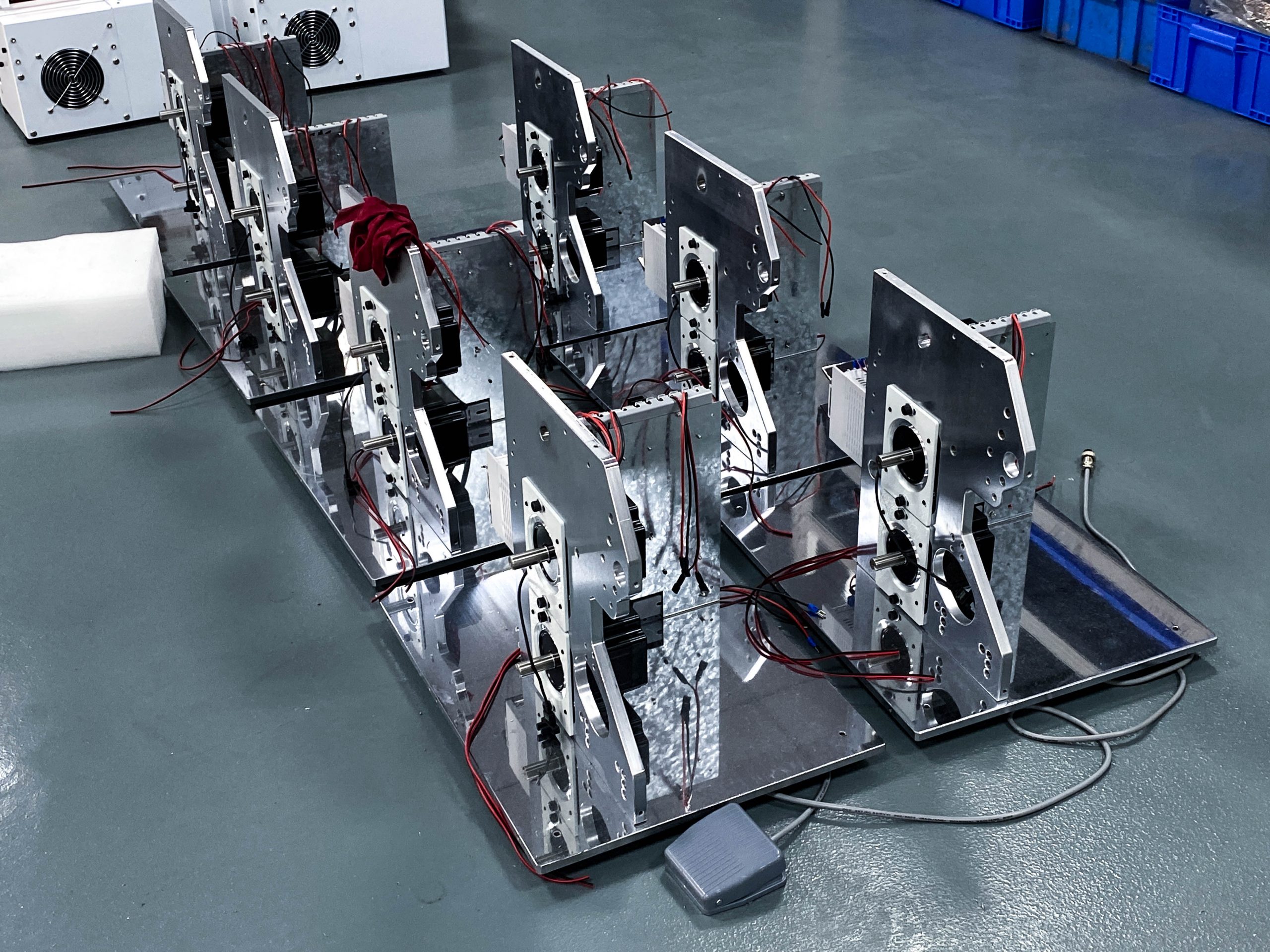

White-Label & Factory Setup

Video Demo

Benefits vs Manual or Semi-Automatic Methods

- 5–10× higher throughput — With automatic loading and infrared heating, cycle times drop to 3–5 seconds per cable.

- ±0.1 mm tolerance — Digital control maintains consistent tubing length and overlap.

- Lower waste — Fully sealed ends prevent fraying and reject rates fall drastically.

- Worker safety — No open flames or manual handling of hot tubing reduces burns and fatigue.

- Traceable quality — Data logging supports ISO/IPC compliance in medical, automotive, and aerospace industries.

Choosing the Right Model

- Low volume & prototyping — Use semi-auto bench-top systems

- Medium-high volume — Fully automatic units with tube feeding and programmable length

- ERP integration — PLC control, program storage, and interlock safety

Major Brands vs Local Manufacturers

- Support network: Global brands offer worldwide parts and service

- Flexibility: Local factories customize fixtures faster

- Cost: Trading firms offer competitive pricing but ensure they verify OEM capabilities.

Our Solution & Advantages

- ISO9001 certified factory with full QC inspection

- Models like KK-T02, KK-T04, KK-TC02 integrated into production lines

- Custom tooling for wire diameters 3–25 mm

- CE/UL safety approvals and 12‑month warranty

- On-site training and 24/7 support

Relevant Standards & Resources

FAQ

Q: Can this machine handle multi-core wire?

A: Yes, standard models manage up to 15 mm diameter or custom clamps available.

Q: Is it safe for Teflon tubing?

A: Absolutely. Temperature zones adjustable to handle specialty tubing.

Q: What maintenance is required?

A: Monthly blade check, quarterly calibration advised; few consumables required.

Q: Can it integrate with robot arms?

A: Yes, options with PLC and I/O allow automation cell integration.

📩 Contact Us for Quote & Support

A: Yes, standard models manage up to 15 mm diameter or custom clamps available.

Q: Is it safe for Teflon tubing?

A: Absolutely. Temperature zones adjustable to handle specialty tubing.

Q: What maintenance is required?

A: Monthly blade check, quarterly calibration advised; few consumables required.

Q: Can it integrate with robot arms?

A: Yes, options with PLC and I/O allow automation cell integration.