⚙️ Ultimate Guide: Wire Cutting & Crimping Machines – Performance, Components & Maintenance (2025)

Keywords: wire cutting and crimping machine, terminal crimping, cable processing machine, crimping blade, wire harness

🔹 Introduction: The Backbone of Modern Wire Harness Processing

Wire cutting and crimping machines play a critical role in modern cable assembly lines. With industries like automotive, electrical panels, and consumer electronics demanding high-speed and high-precision cable processing, automatic machines are now the backbone of production.

🔧 Section 1: Main Components of a Wire Cutting & Crimping Machine

| Component | Function |

|---|---|

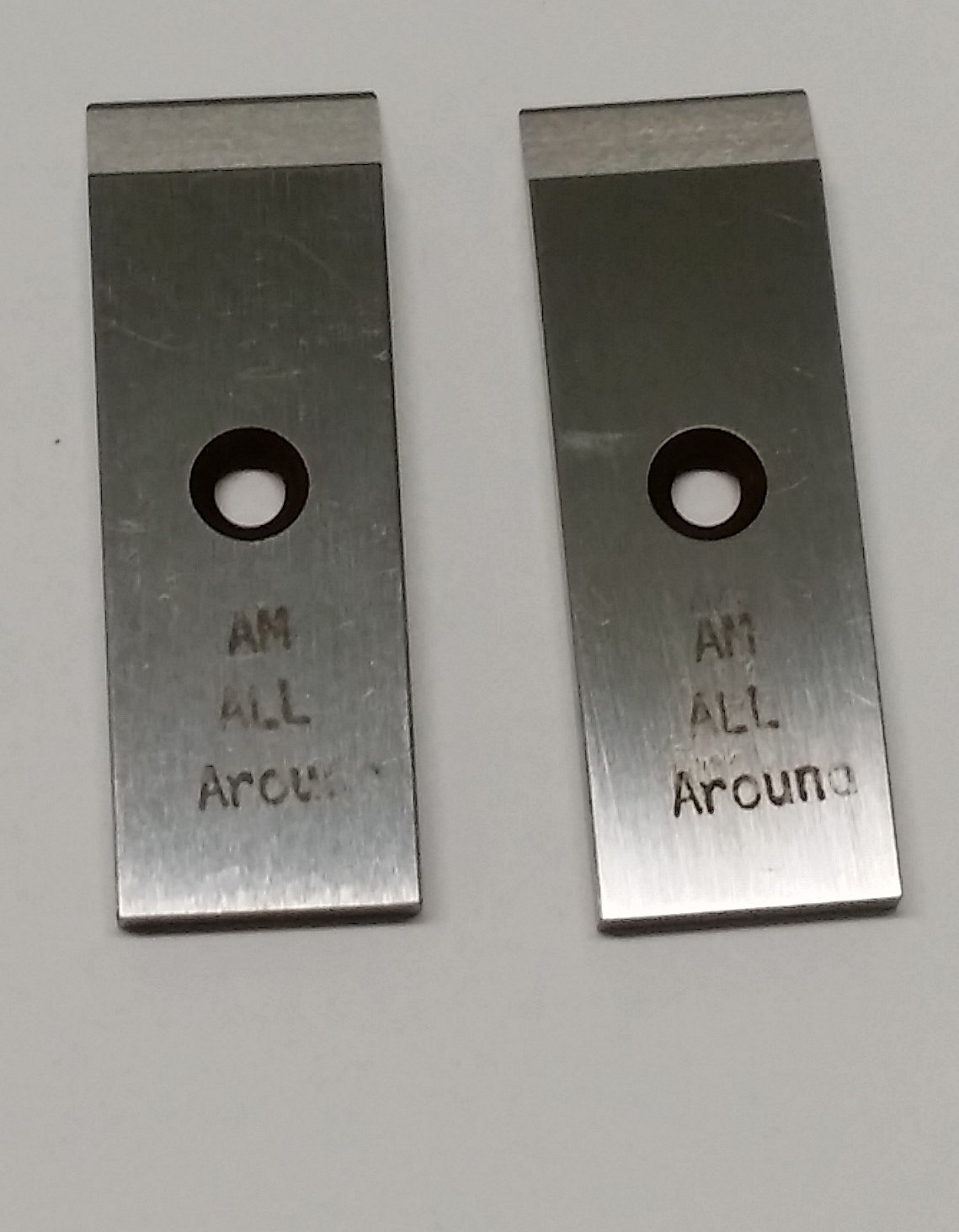

| Cutting Blades | Precision wire length cutting |

| Stripping Unit | Removes insulation for proper crimping |

| Crimping Module | Automates terminal crimping process |

| Motor System | Synchronizes wire feed and crimp timing |

| Control Panel | Operator interface and diagnostics |

🏭 Section 2: Our Factory Process & Machine Packaging

Every machine at our factory goes through rigorous testing and quality checks. From parts assembly to final trial runs, we ensure each unit matches global standards.

- Step-by-step quality control from component to whole-machine testing

- High-precision calibration before packaging

- Safe international shipping with solid wood crates

🛠️ Section 3: Maintenance Guide for Long-Term Stability

Routine maintenance ensures reliability and long machine lifespan. Here’s a simple checklist:

- Daily: Clean cutting and crimping areas; check for blade debris

- Weekly: Lubricate feeding gears; clean wire guides

- Monthly: Check crimping precision and recalibrate wire length

💡 Section 4: Optimization Tips & Performance Enhancements

- Upgrade to tungsten-alloy blades for extended cutting life

- Use high-efficiency servo motors for wire feed consistency

- Optimize crimping angle and depth based on terminal model

- Install dust sensors to avoid contamination in crimp modules

🔗 Internal & External SEO Strategy

Internal Links:

External References: