Machines Behind Wire Harnesses: What Equipment Makes It Possible?

Modern industries—from automotive to electronics and renewable energy—depend on wire harnesses to transmit power and signals reliably. But few people realize how many specialized machines are required to produce them. Every stage, from cutting to crimping and sealing, depends on high-precision automation.

At CableMachineries (cablemachineries.com), we design and manufacture a complete range of wire processing machines that power this transformation. Below, we’ll explore the main types of equipment behind professional wire harness manufacturing and how they work together to ensure precision, speed, and reliability.

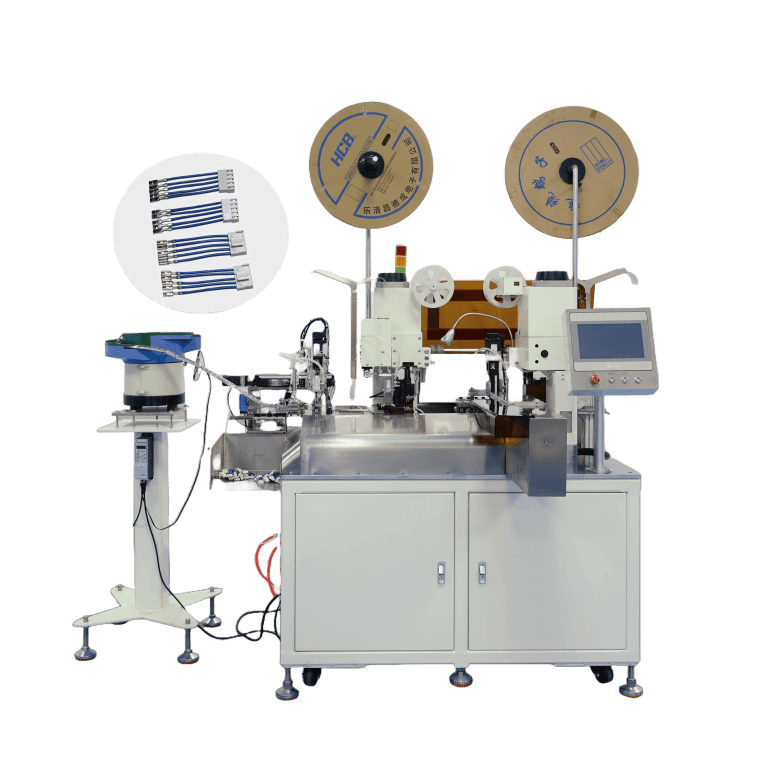

Automatic Wire Cutting and Stripping Machines

The production of a wire harness starts with cutting and stripping individual wires to precise lengths. Automatic wire cutting and stripping machines handle this task with high speed and accuracy.

For instance, the KK-501 Double-Wire Stripping Machine from CableMachineries processes two wires simultaneously, covering sizes from AWG 32 to 18 with a cutting tolerance of ±0.05mm. It can also perform multi-stage stripping for complex harness designs, saving significant manual effort.

Well-known brands like Komax and TE Connectivity have long advanced this field, but CableMachineries specializes in making cost-effective, customizable machines suitable for small and mid-sized factories worldwide.

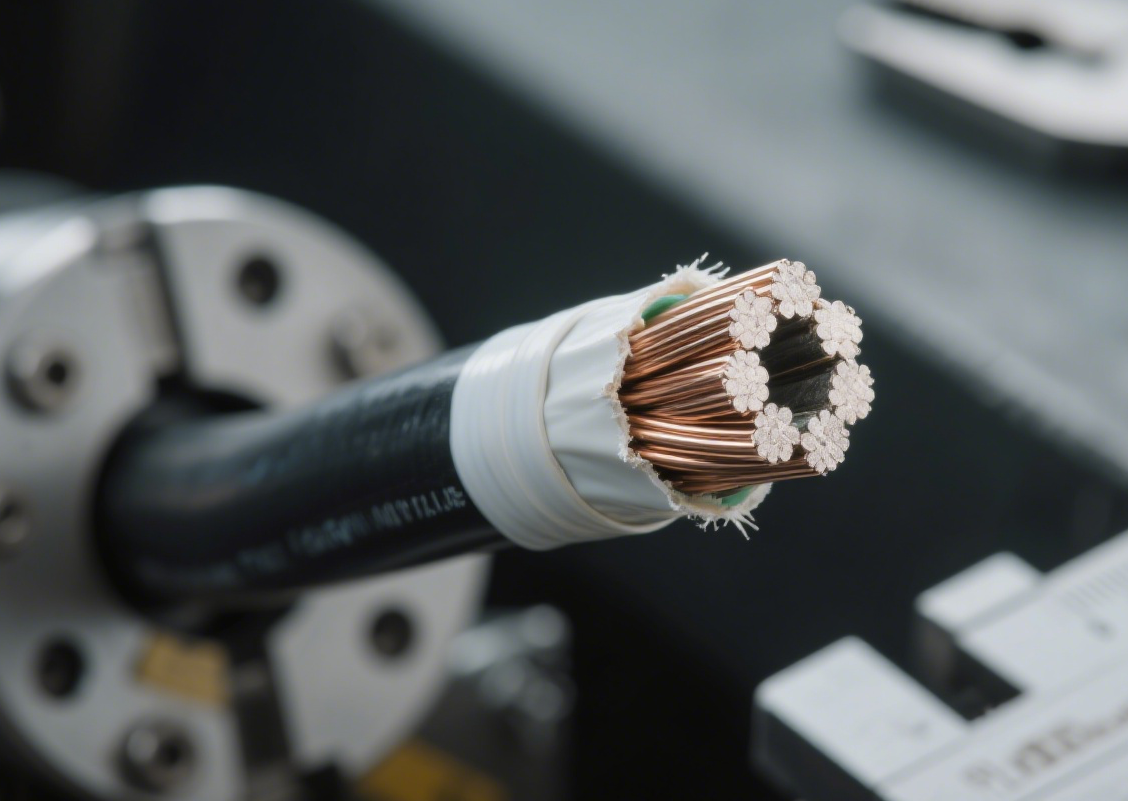

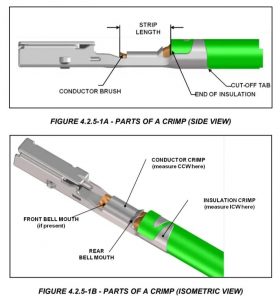

Terminal Crimping Machines

Once the wire ends are stripped, metal terminals are attached to ensure strong electrical and mechanical connections. This step uses terminal crimping machines, which apply controlled force to compress the terminal barrel around the wire strands.

CableMachineries’ KKL-3T Terminal Crimping Machine provides stable, repeatable crimping results thanks to its servo-driven precision. Compared to manual crimping, automated machines minimize variability, reduce operator fatigue, and ensure compliance with the IPC/WHMA-A-620 standard for crimp integrity.

In modern factories, crimping is often integrated with cutting and stripping into a continuous production line for higher efficiency.

Seal and Waterproof Plug Insertion Machines

In industries such as automotive and outdoor electronics, waterproofing is essential. Seal insertion machines automatically place rubber plugs or silicone grommets before or after crimping.

For example, CableMachineries’ Automatic Crimping & Waterproof Seal Insertion Machine combines multiple processes—cutting, stripping, crimping, and sealing—into one integrated workflow. This not only improves speed and consistency but also achieves IP67 protection standards required for high-end harnesses.

Automation in this step reduces manual errors and improves sealing uniformity, which is crucial for long-term reliability in harsh environments. Leading automation firms like SDC Automation also develop advanced waterproof plug insertion systems for EV and hybrid vehicle harnesses.

Heat Shrink Tubing and Sealing Machines

After assembly, harnesses often undergo heat shrink tubing to add insulation, strain relief, and environmental protection. Automatic heat shrink tubing machines automatically feed, cut, and heat the tubing, applying consistent thermal energy for a perfect fit.

CableMachineries’ Automatic Heat Shrink Tubing Machine is designed for uniform heating and adjustable temperature control, making it suitable for aerospace, medical, and industrial applications where vibration and temperature resistance are vital.

Uniform shrinkage ensures wires remain firmly insulated and protected, preventing wire fatigue and extending harness lifespan.

Vision Inspection and Electrical Testing

Every professional wire harness must pass strict quality control checks before shipping. Modern production lines integrate vision inspection systems that detect terminal orientation errors, missing seals, insulation damage, or color mismatches.

CableMachineries integrates AI-assisted vision inspection modules capable of detecting deviations within 0.02mm. These systems ensure each harness meets design specifications before it proceeds to testing.

Electrical testing machines then verify continuity, insulation resistance, and grounding. According to IPC/WHMA-A-620, these tests ensure that each harness can perform safely under expected voltage and environmental conditions. This combination of visual and electrical inspection forms the backbone of modern quality assurance.

Wire Bundling and Taping Equipment

After testing, wires are grouped neatly using automatic taping or bundling machines. These machines wrap harnesses with PVC, cloth, or spiral tape for protection and organization.

CableMachineries offers fully automated taping systems that reduce manual labor and ensure consistent wrapping tension. The result is a clean, professional appearance and improved durability. Automated bundling also reduces the risk of wire crossing and simplifies installation in vehicles, machinery, or control cabinets.

Integrated Harness Production Lines

As automation technology advances, many manufacturers are adopting integrated harness assembly lines that connect cutting, stripping, crimping, sealing, and inspection stations.

CableMachineries provides modular systems that integrate with MES and barcode tracking, allowing full process traceability. These lines enable real-time monitoring of production data, predictive maintenance, and batch-level quality reports—features that are becoming essential in automotive, EV, and industrial automation sectors.

Such integration minimizes manual intervention, boosts throughput, and ensures each finished harness is fully compliant with international standards.

Conclusion

The creation of a wire harness is far more sophisticated than it appears. Behind every cable assembly lies a network of advanced machinery—cutting, stripping, crimping, sealing, inspecting, and bundling—all working in harmony.

Whether you’re building simple control cables or complex automotive wiring systems, automation guarantees accuracy, safety, and repeatability.

If you’re exploring ways to upgrade or automate your wire harness production, visit CableMachineries.com to explore a full range of wire cutting, stripping, crimping, and sealing equipment—or contact our team for customized solutions that match your production goals.